Search the Special Collections and Archives Portal

Search Results

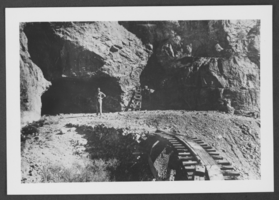

Photograph of Ed Carbary at Potosi Mine, Nevada, circa late 1800s to early 1900s

Date

1870 to 1939

Archival Collection

Description

Ed Carbary standing at the entrance to Potosi Mine in Nevada.

Image

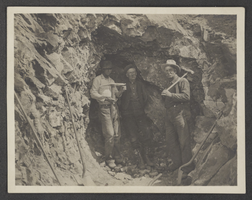

Photograph of miners at Badger Hole, circa early to mid 1900s

Date

1900 to 1959

Archival Collection

Description

Three unidentified miners at Badger Hole, possibly at the Badger Lead Mine in Nevada.

Image

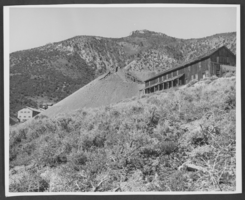

Photograph of Yellow Jacket Mine, Gold Hill, Nevada, circa early 1900s

Date

1900 to 1910

Archival Collection

Description

Yellow Jacket Mine.

Image

Photograph of mining site, Eureka, Nevada, circa early 1900s

Date

1900 to 1910

Archival Collection

Description

Eureka, Nevada mining site.

Image

Photograph of Quartette Mine, Searchlight, Nevada, circa early 1900s

Date

1900 to 1910

Archival Collection

Description

Description provided with image: "Head works, Quartette Mine, Searchlight, Nevada."

Image

Photograph of open pit mine, Ruth, Nevada, 1934

Date

1934

Archival Collection

Description

Open pit mine.

Image

Slide of Carlin Mine, Nevada, circa 1960s

Date

1960 to 1969

Archival Collection

Description

Carlin open pit gold mine in Nevada.

Image

Slide of open pit, Weed Heights, Nevada, May 1966

Date

1966-05

Archival Collection

Description

An open pit at Weed Heights, Nevada.

Image

Slide of copper mine, Battle Mountain, Nevada, circa 1960s

Date

1960 to 1969

Archival Collection

Description

Copper mine area at Battle Mountain in Nevada.

Image

Slide of the old stamp mill, circa 1950s

Date

1950 to 1959

Archival Collection

Description

The old stamp mill, location unknown. A stamp mill (or stamp battery or stamping mill) is a type of mill machine that crushes material by pounding rather than grinding, either for further processing or for extraction of metallic ores. Breaking material down is a type of unit operation. A stamp mill consists of a set of heavy steel (iron-shod wood in some cases) stamps, loosely held vertically in a frame, in which the stamps can slide up and down. They are lifted by cams on a horizontal rotating shaft. On modern mills, the cam is arranged to lift the stamp from the side, so that it causes the stamp to rotate. This evens the wear on the shoe at the foot of the stamp. As the cam moves from under the stamp, the stamp falls onto the ore below, crushing the rock, and the lifting process is repeated at the next pass of the cam. Each one frame and stamp set is sometimes called a "battery" or, confusingly, a "stamp" and mills are sometimes categorized by how many stamps they have, i.e. a "10 stamp mill" has 10 sets. They usually are arranged linearly, but when a mill is enlarged, a new line of them may be constructed rather than extending the line. Abandoned mill sites (as documented by industrial archaeologists) will usually have linear rows of foundation sets as their most prominent visible feature as the overall apparatus can exceed 20 feet in height, requiring large foundations. Stamps are usually arranged in sets of five. Some ore processing applications used large quantities of water so some stamp mills are located near natural or artificial bodies of water. For example, the Redridge Steel Dam was built to supply stamp mills with process water.

Image

Pagination

Refine my results

Content Type

Creator or Contributor

Subject

Archival Collection

Digital Project

Resource Type

Year

Material Type

Place

Language

Records Classification