Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

Member of

More Info

Rights

Digital Provenance

Publisher

Transcription

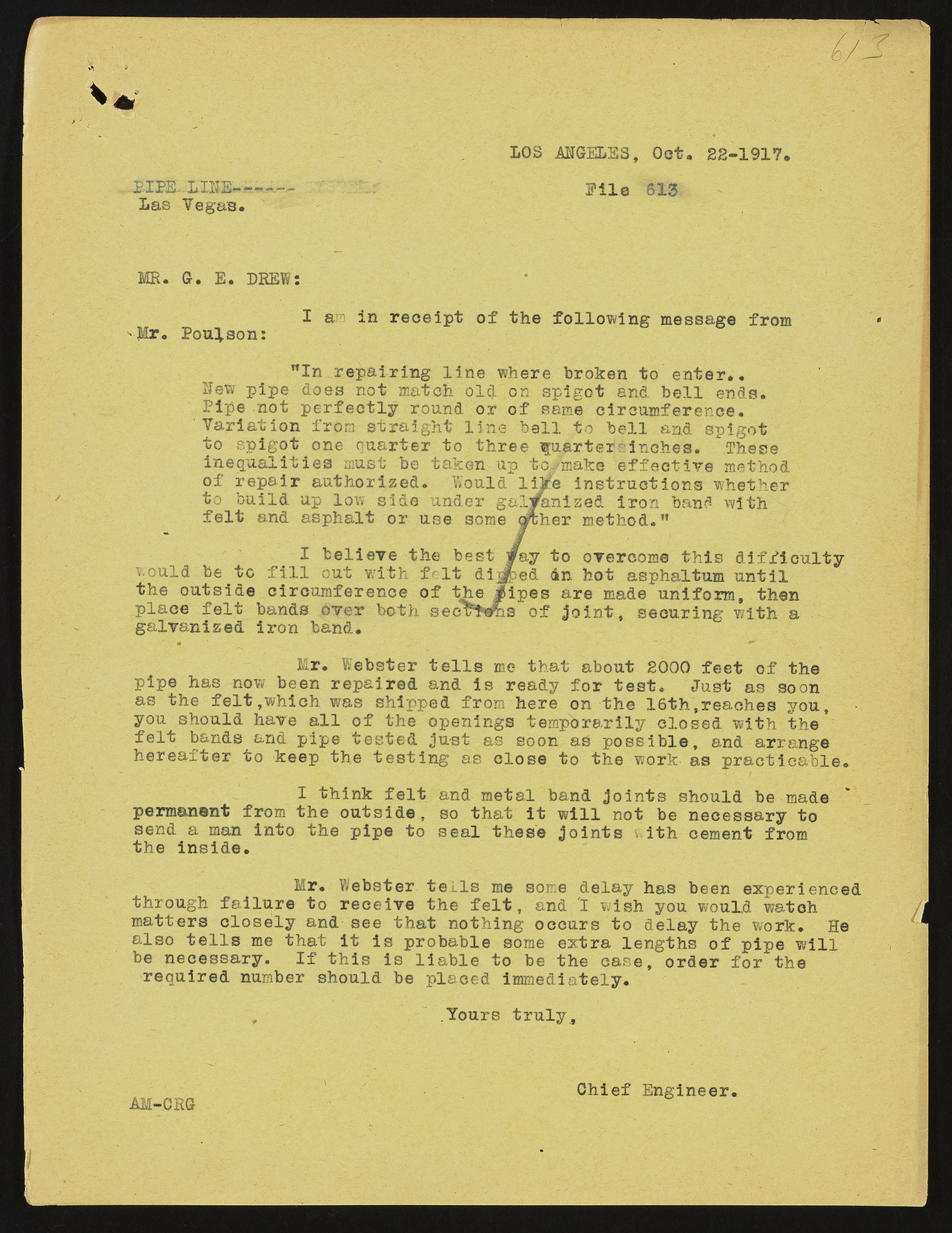

LOS ANGELES, Oet. 22-1917. RIPE-.LINE, M l © 613 Las Vegas MR. G. E. DREW: ?'Mr. Poulson: I ara in receipt of the following message from "In repairing line where broken to enter.. New pipe does not match old on spigot and bell ends. Pipe not perfectly round or of same circumference. Variation from straight line bell to bell and spigot to spigot one quarter to three iuarteroinch.es. "’These inequalities must be taken up to/make effective method of repair authorized. Would lijft instructions whether to build up low side under galvanized iron band with felt and asphalt or use some ipfeier method.” would be to fill out with felt di id &n hot asphaltum until the outside circumference of the JSipes are made uniform, then place felt bands over both seo%fes of joint, securing with a galvanized iron band. pipe has now been repaired and is ready for test. Just as soon as the felt,which was shipped from here on the 16th,reaches you, you should have all of the openings temporarily closed with the felt bands and pipe tested just as soon as possible, and arrange hereafter to keep the testing as close to the work as practicable. permanent from the outside, so that it will not be necessary to send a man into the pipe to seal these joints with cement from the inside. through failure to receive the felt, and 1 wish you would watch matters closely and see that nothing occurs to delay the work. He also tells me that it is probable some extra lengths of pipe will be necessary. If this is liable to be the case, order for the required number should be placed immediately. I believe the best ty to overcome this difficulty Mr. Webster tells me that about 2000 feet of the I think felt and metal band joints should be made Mr. Webster tells me some delay has been experienced .Yours truly, AM-CRG Chief Engineer