Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

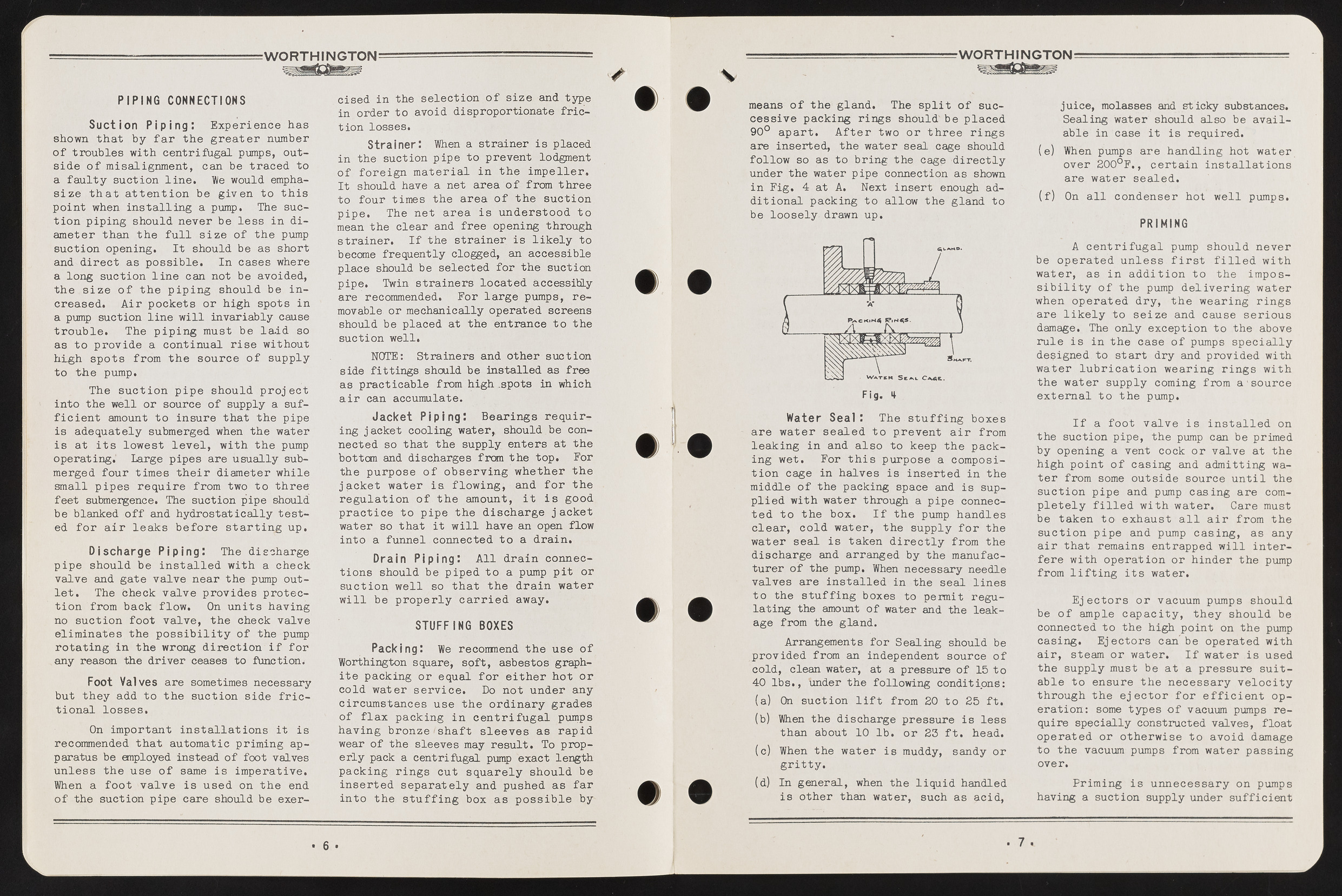

W O R TH IN G TO N PIPING CONNECTIONS S u ctio n P ip in g : Experience has shown that by far the greater number of troubles with centrifugal pumps, outside of misalignment, can be traced to a faulty suction line. Vie would emphasize that attention be given to this point when installing a pump. The suction piping should never be less in diameter than the full size of the pump suction opening. It should be as short and direct as possible. In cases where a long suction line can not be avoided, the size of the piping should be increased. Air pockets or high spots in a pump suction line will invariably cause trouble. The piping must be laid so as to provide a continual rise without high spots from the source of supply to the pump. The suction pipe should project into the well or source of supply a sufficient amount to insure that the pipe is adequately submerged when the water is at its lowest level, with the pump operating.' Large pipes are usually submerged four times their diameter while small pipes require from two to three feet submergence. The suction pipe should be blanked off and hydrostatically tested for air leaks before starting up. D ischarge P ip in g : The discharge pipe should be installed with a check valve and gate valve near the pump outlet. The check valve provides protection from back flow. On units having no suction foot valve, the check valve eliminates the possibility of the pump rotating in the wrong direction if for any reason the driver ceases to function. Foot Val ves are sometimes necessary but they add to the suction side frictional losses. On important installations it is recommended that automatic priming apparatus be employed instead of foot valves unless the use of same is imperative. When a foot valve is used on the end of the suction pipe care should be exercised in the selection of size and type in order to avoid disproportionate friction losses. Strain e r: When a strainer is placed in the suction pipe to prevent lodgment of foreign material in the impeller. It should have a net area of from three to four times the area of the suction pipe. The net area is understood to mean the clear and free opening through strainer. If the strainer is likely to become frequently clogged, an accessible place should be selected for the suction pipe. Twin strainers located accessibly are recommended. For large pumps, removable or mechanically operated screens should be placed at the entrance to the suction well. NOTE: Strainers and other suction side fittings should be installed as free as practicable from high .spots in which air can accumulate. Ja c k e t P ip in g : Bearings requiring jacket cooling water,, should be connected so that the supply enters at the bottom and discharges from the top. For the purpose of observing whether the jacket water is flowing, and for the regulation of the amount, it is good practice to pipe the discharge jacket water so that it will have an open flow into a funnel connected to a drain. Drain P ip in g : All drain connections should be piped to a pump pit or suction well so that the drain water will be properly carried away. STUFFING BOXES Packing: We recomnend the use of Worthington square, soft, asbestos graphite packing or equal for either hot or cold water service. Do not under any circumstances use the ordinary grades of flax packing in centrifugal pumps having bronze'shaft sleeves as rapid wear of the sleeves may result. To properly pack a centrifugal pump exact length packing rings cut squarely should be inserted separately and pushed as far into the stuffing box as possible by • 6 • j V W O R TH IN G TO N means of the gland. The split of successive packing rings should be placed 90° apart. After two or three rings are inserted, the water seal cage should follow so as to bring the cage directly under the water pipe connection as shown in Fig. 4 at A. Next insert enough additional packing to allow the gland to be loosely drawn up. Water S e a l: The stuffing boxes are water sealed to prevent air from leaking in and also to keep the packing wet. For this purpose a composition cage in halves is inserted in the middle of the packing space and is supplied with water through a pipe connected to the box. If the pump handles clear, cold water, the supply for the water seal is taken directly from the discharge and arranged by the manufacturer of the pump. When necessary needle valves are installed in the seal lines to the stuffing boxes to permit regulating the amount of water and the leakage from the gland. Arrangements for Sealing should be provided from an independent source of cold, clean water, at a pressure of 15 to 40 lbs., under the following conditions: (a) On suction lift from 20 to 25 ft. (b) When the discharge pressure is less than about 10 lb. or 23 ft. head. (c) When the water is muddy, sandy or gritty. (d) In general, when the liquid handled is other than water, such as acid, juice, molasses and sticky substances. Sealing water should also be available in case it is required. (e) When pumps are handling hot water over 200°F., certain installations are water sealed. (f) On all condenser hot well pumps. PRIMING A centrifugal pump should never be operated unless first filled with water, as in addition to the impossibility of the pump delivering water when operated dry, the wearing rings are likely to seize and cause serious damage. The only exception to the above rule is in the case of pumps specially designed to start dry and provided with water lubrication wearing rings with the water supply coming from a source external to the pump. If a foot valve is installed on the suction pipe, the pump can be primed by opening a vent cock or valve at the high point of casing and admitting water from some outside source until the suction pipe and pump casing are completely filled with water. Care must be taken to exhaust all air from the suction pipe and pump casing, as any air that remains entrapped will interfere with operation or hinder the pump from lifting its water. Ejectors or vacuum pumps should be of ample capacity, they should be connected to the high point on the pump casing. Ejectors can be operated with air, steam or water. If water is used the supply must be at a pressure suitable to ensure the necessary velocity through the ejector for efficient operation: some types of vacuum pumps require specially constructed valves, float operated or otherwise to avoid damage to the vacuum pumps from water passing over. Priming is unnecessary on pumps having a suction supply under sufficient . 7 .