Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

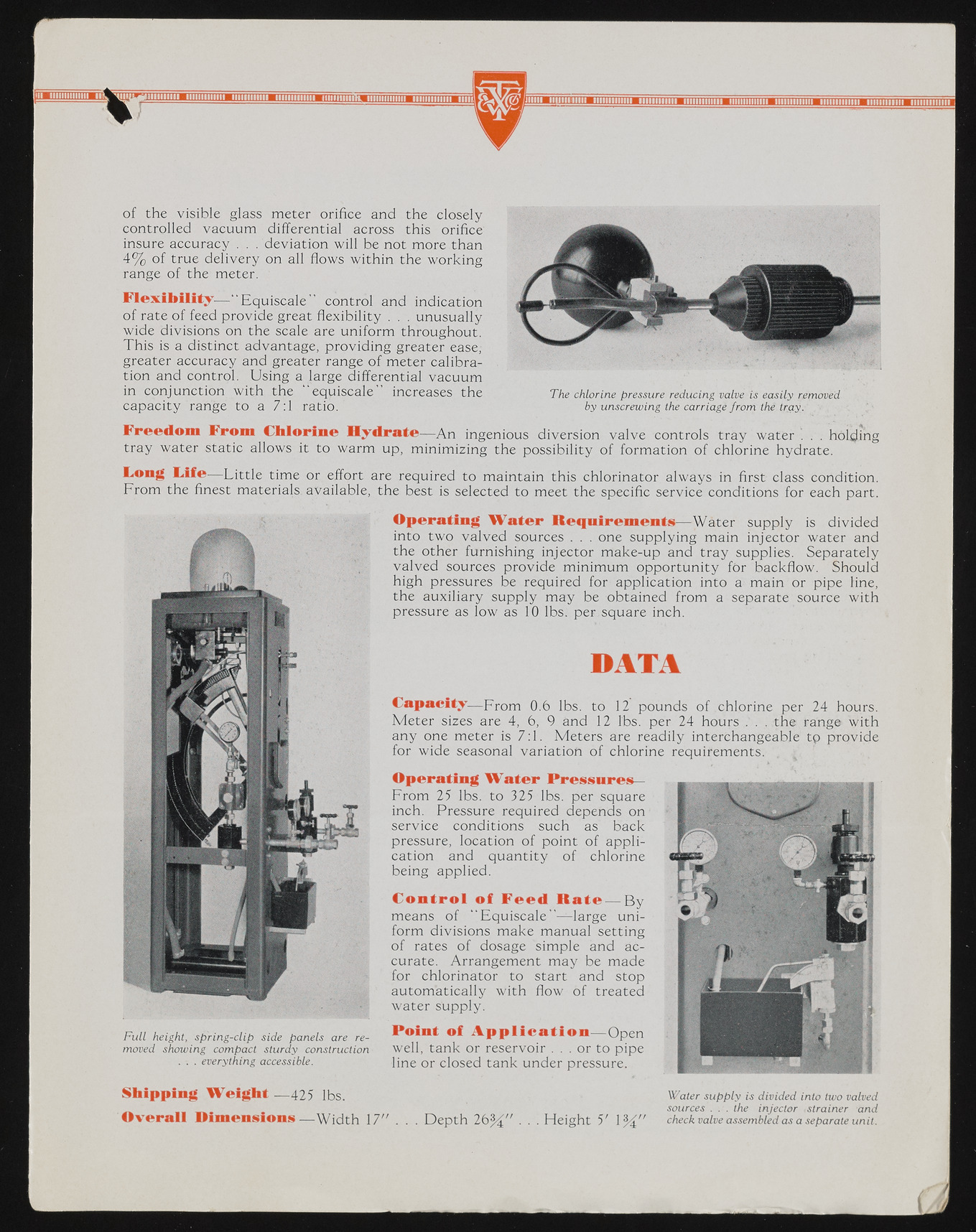

of the visible glass meter orifice and the closely controlled vacuum differential across this orifice insure accuracy . . . deviation will be not more than 4 % of true delivery on all flows within the working range of the meter. F lexib ility— Equiscale” control and indication of rate of feed provide great flexibility . . . unusually wide divisions on the scale are uniform throughout. This is a distinct advantage, providing greater ease; greater accuracy and greater range of meter calibration and control. Using a large differential vacuum in conjunction with the “ equiscale” increases the capacity range to a 7:1 ratio. The chlorine pressure reducing valve is easily removed by unscrewing the carriage from the tray. F reed om F rom C hlorine H yd rate— An ingenious diversion valve controls tray water . . . holding tray water static allows it to warm up, minimizing the possibility of formation of chlorine hydrate. C®og C ife— Little time or effort are required to maintain this chlorinator always in first class condition. From the finest materials available, the best is selected to meet the specific service conditions for each part. Full height, spring-clip side panels are removed showing compact sturdy construction . . . everything accessible. O perating W a te r R equ irem en ts— Water supply is divided into two valved sources . . . one supplying main injector water and the other furnishing injector make-up and tray supplies. Separately valved sources provide minimum opportunity for backflow. Should high pressures be required for application into a main or pipe line, the auxiliary supply may be obtained from a separate source with pressure as low as 10 lbs. per square inch. DATA Capacity— From 0.6 lbs. to 12 pounds of chlorine per 24 hours. Meter sizes are 4, 6, 9 and 12 lbs. per 24 hours . . . the range with any one meter is 7:1. Meters are readily interchangeable tp provide for wide seasonal variation of chlorine requirements. O perating W a te r P ressu res— From 25 lbs. to 325 lbs. per square inch. Pressure required depends on service conditions such as back pressure, location o f point of application and quantity of chlorine being applied. C o n t r o l o f F e e d R a t e — By means of “ Equiscale ’’— large uniform divisions make manual setting of rates of dosage simple and accurate. Arrangement may be made for chlorinator to start and stop automatically with flow of treated water supply. P oint of A p p l i c a t i o n — Open well, tank or reservoir . . . or to pipe line or closed tank under pressure. S h ip p in g 3W^eight— 425 lbs. Water supply is divided into two valved „ sources . . . the injector ,strainer and O v e r a ll D im e n s io n s ^ W id t h 17" . . . Depth 26%" . . . Height 5' \%" check valve assembled as a separate unit.