Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

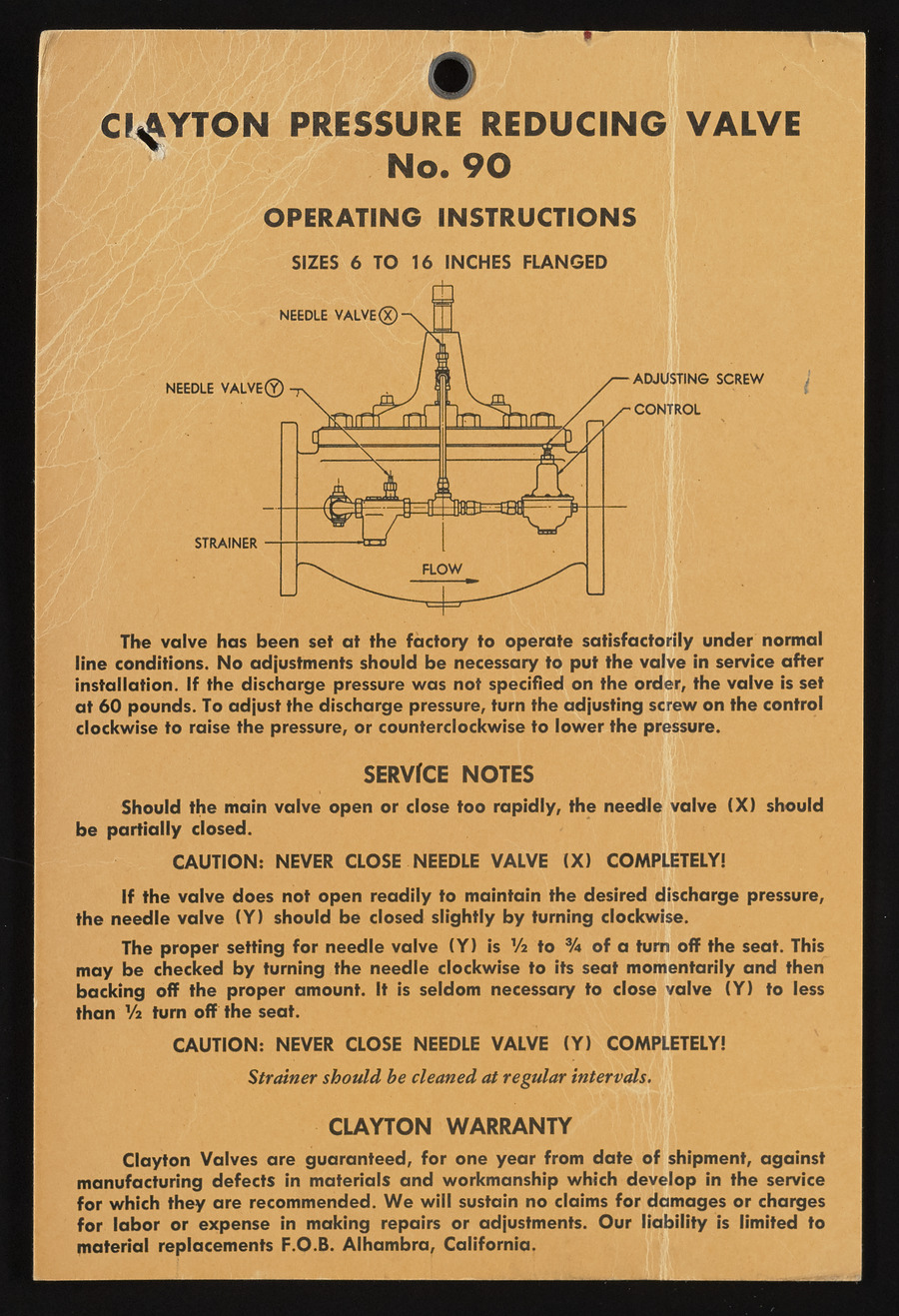

CI^YTON PRESSURE REDUCING VALVE No. 90 OPERATING INSTRUCTIONS -ADJUSTING SCREW ?CONTROL The valve has been set at the factory to operate satisfactorily under normal line conditions. No adjustments should be necessary to put the valve in service after installation. If the discharge pressure was not specified on the order, the valve is set at 60 pounds. To adjust the discharge pressure, turn the adjusting screw on the control clockwise to raise the pressure, or counterclockwise to lower the pressure. SERVICE NOTES Should the main valve open or close too rapidly, the needle valve (X) should be partially closed. CAUTION: NEVER CLOSE NEEDLE VALVE (X) COMPLETELY! If the valve does not open readily to maintain the desired discharge pressure, the needle valve (Y) should be closed slightly by turning clockwise. The proper setting for needle valve (Y) is 'A to % of a turn off the seat. This may be checked by turning the needle clockwise to its seat momentarily and then backing off the proper amount. It is seldom necessary to close valve (Y) to less than % turn off the seat. CAUTION: NEVER CLOSE NEEDLE VALVE (Y) COMPLETELY! Strainer should be cleaned at regular intervals. CLAYTON WARRANTY Clayton Valves are guaranteed, for one year from date of shipment, against manufacturing defects in materials and workmanship which develop in the service for which they are recommended. We will sustain no claims for damages or charges for labor or expense in making repairs or adjustments. Our liability is limited to material replacements F.O.B. Alhambra, California.