Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

Member of

More Info

Rights

Digital Provenance

Publisher

Transcription

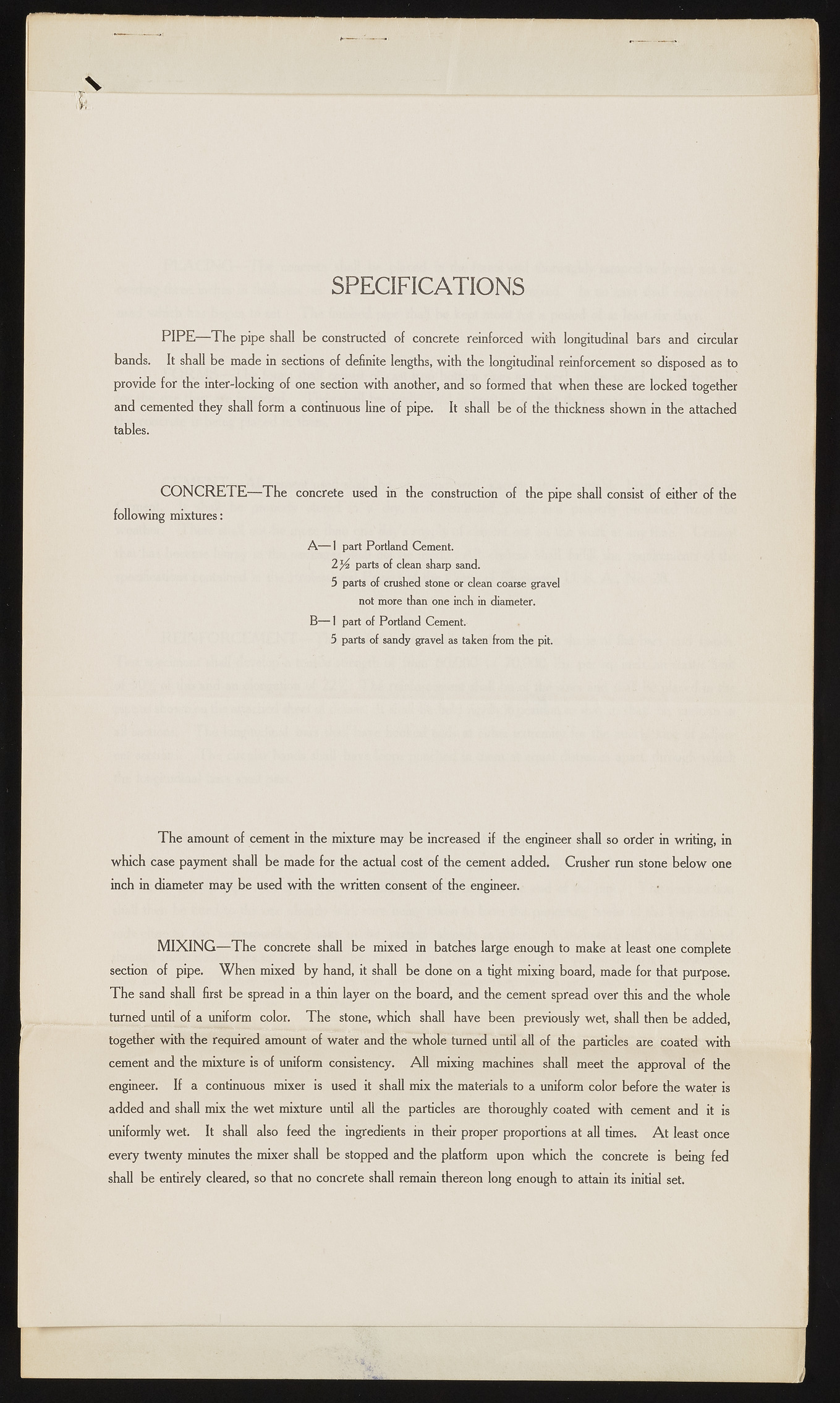

? I; SPEC IFIC ATIO N S P I P E — T h e pipe shall be constructed of concrete reinforced with longitudinal bars and circular bands. It shall be made in sections of definite lengths, with the longitudinal reinforcement so disposed as to provide for the inter-locking of one section with another, and so formed that when these are locked together and cemented they shall form a continuous line of pipe. It shall be of the thickness shown in the attached tables. C O N C R E T E — T h e concrete used in the construction of the pipe shall consist of either of the following mixtures: A — 1 part P ortla n d C em en t. 2Yi parts o f clean sharp sand. 5 parts o f crushed stone or clean coarse g ra vel not m ore than o n e inch in diam eter. B — 1 part o f P ortlan d C em ent. 5 parts o f sandy gravel as taken from th e pit. T h e amount of cement in the mixture may be increased if the engineer shall so order in writing, in which case payment shall be made for the actual cost of the cement added. Crusher run stone below one inch in diameter may be used with the written consent of the engineer. M I X I N G — T h e concrete shall be mixed in batches large enough to make at least one complete section of pipe. W h en mixed by hand, it shall be done on a tight mixing board, made for that purpose. T h e sand shall first be spread in a thin layer on the board, and the cement spread over this and the whole turned until of a uniform color. T h e stone, which shall have been previously wet, shall then be added, together with the required amount of water and the whole turned until all of the particles are coated with cement and the mixture is of uniform consistency. A ll mixing machines shall meet the approval of the engineer. If a continuous mixer is used it shall mix the materials to a uniform color before the water is added and shall mix the w et mixture until all the particles are thoroughly coated with cement and it is uniformly wet. It shall also feed the ingredients in their proper proportions at all times. A t least once every twenty minutes the mixer shall be stopped and the platform upon which the concrete is being fed shall be entirely cleared, so that no concrete shall remain thereon long enough to attain its initial set.