Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

Member of

More Info

Rights

Digital Provenance

Publisher

Transcription

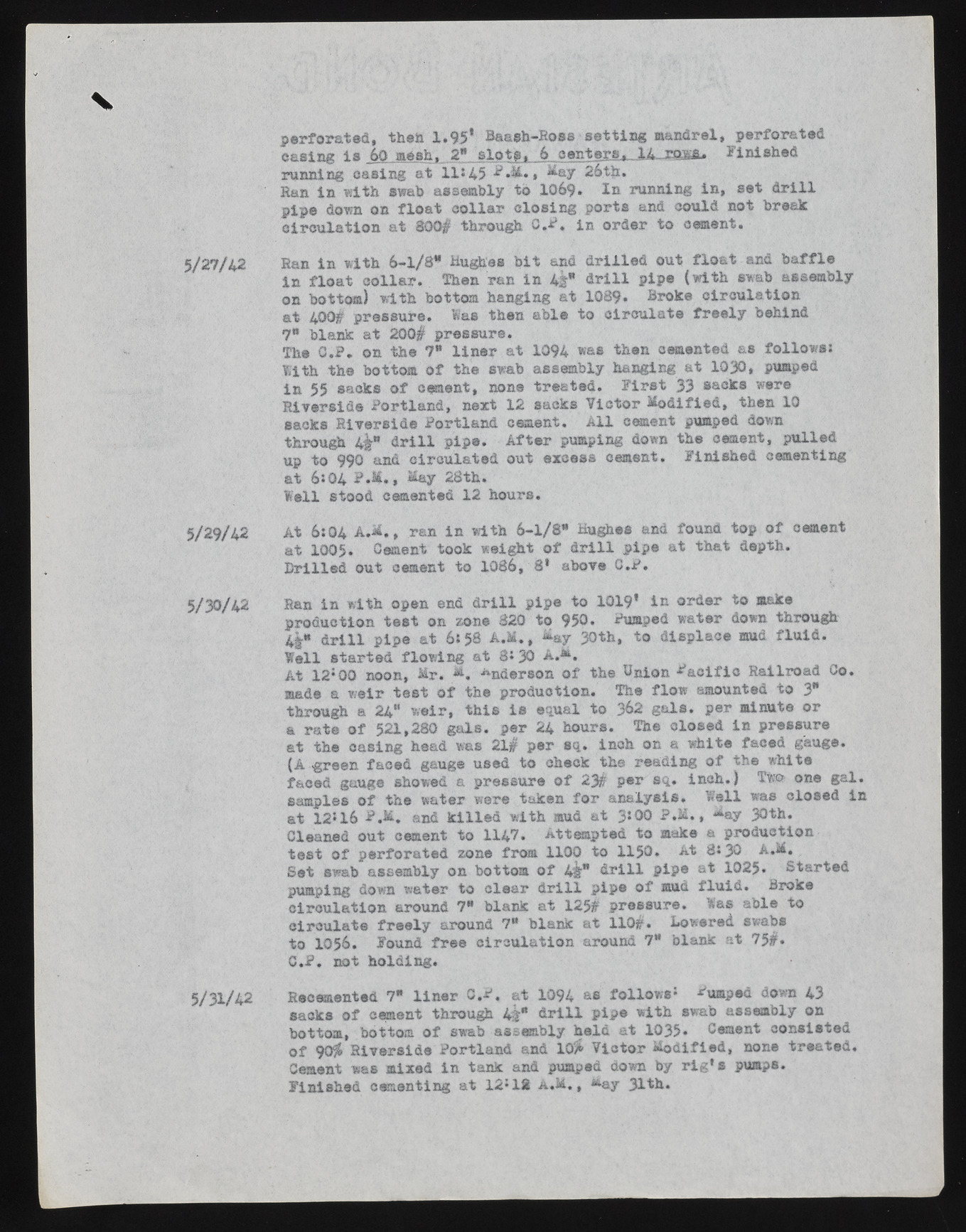

5/27/-W 5/29/42 5/30/42 5/31/42 p erfo rated , then 1.95* Baugh-Rose se ttin g mandrel, perforated casing I s 60 mesh. 2" s lo ts . 6 canters* XA^rsmsu Finished running casing at 1 1 ? 45 P*M ., May 26th. Ran in with swab assembly to 1069 * In running in , set d r i l l pipe down on flo a t c o lla r c lo sin g ports and could not break c irc u la tio n at 800# through C.P. in order to cement. Ran in with 6-1/8* Hughes b it and d r ille d out flo a t and b a f f le in flo a t c o lla r . Then ran in 4&" d r i l l pipe (w ith swab assembly on bottom) with bottom hanging a t 1089. Broke c irc u la tio n at 400# pressure, la s then a b le to c irc u la te fr e e ly behind 7 “ blank at 200# pressure. The C.P* on the 7* lin e r at 1094 was then cemented as fo llo w s: l i t h the bottom o f the swab assembly hanging at 10 3 0 , pumped in 55 sacks o f cement, non® treated. F ir s t 33 sacks were R iverside Portlan d, next 12 sacks V ic to r M odified, then 10 sacks R iverside Portland cement. A l l cement pumped down through 4§* d r i l l pipe. A fte r pumping down the cement, p u lled up to 990 and circ u la te d out excess cement. Finished cementing at 6:04 P .M ., May 28th. V e il stood cemented 1 2 hours. At 6:04 A .M ., ran in with 6-1/8* Hughes and found top o f cement at 10 0 5 . Cement took weight o f d r i l l pipe at that depth. D r ille d out cement to 1086, 8 * above C.P. Ran in with open end d r i l l pipe to 1019' in order to make production te st on zone 820 to 950. Pumped water down through 4|* d r i l l pipe at 6 :58 A.M ., Majr 30th, to d isplace mud f lu id . V e il started flow in g at 8 :30 A.m . At 12*00 noon, Mr. M, •anderson o f the Onion P a c ific R ailroad Co. made a w eir te s t o f the production. The flow amounted to 3* through a 24” w eir, th is i s equal to 362 gals* per minute or a ra te o f 521,280 g a ls , per 24 hours. The closed in pressure at the Casing head was 21# per sq> inch on a white faced gauge. (A green faced gauge used to check the reading o f the white faced gauge showed a pressure o f 23# per sq. in ch .) Two one g a l. samples o f the water were taken fo r a n a ly sis. W ell was closed in at 1 2 * 1 6 P.M. and k ille d with mud at 3 JO0 I J . , **ay 30th. Cleaned out cement to 1147. Attempted to make a production te st o f p erforated zone from 1100 to 1150. At 8*30 A.M. Set swab assembly on bottom o f 4i?* d r i l l pipe at 1025. Started pumping down water to c le a r d r i l l pipe o f mud flu i d . Broke c irc u la tio n around 7* blank at 125# pressure. Was able to c irc u la te fr e e ly around 7* blank at 110#. Lowered swabs to 1056. Found fre e c irc u la tio n around 7" blank at 75f. C.P. not holding. Recemented 7* lin e r C.P. at 1094 as fo llo w s 1 Pumped down 43 sacks o f cement through At* d r i l l pipe with swab assembly on bottom, bottom o f swab assembly held at 1035* Cement consisted o f 90$ R iversid e Portland and 10$ V ic to r M odified, none treated. Cement was mixed in tank and pumped down by r i g ’ s pumps. Finished cementing at 12*18 A .M ., May 31th.