Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

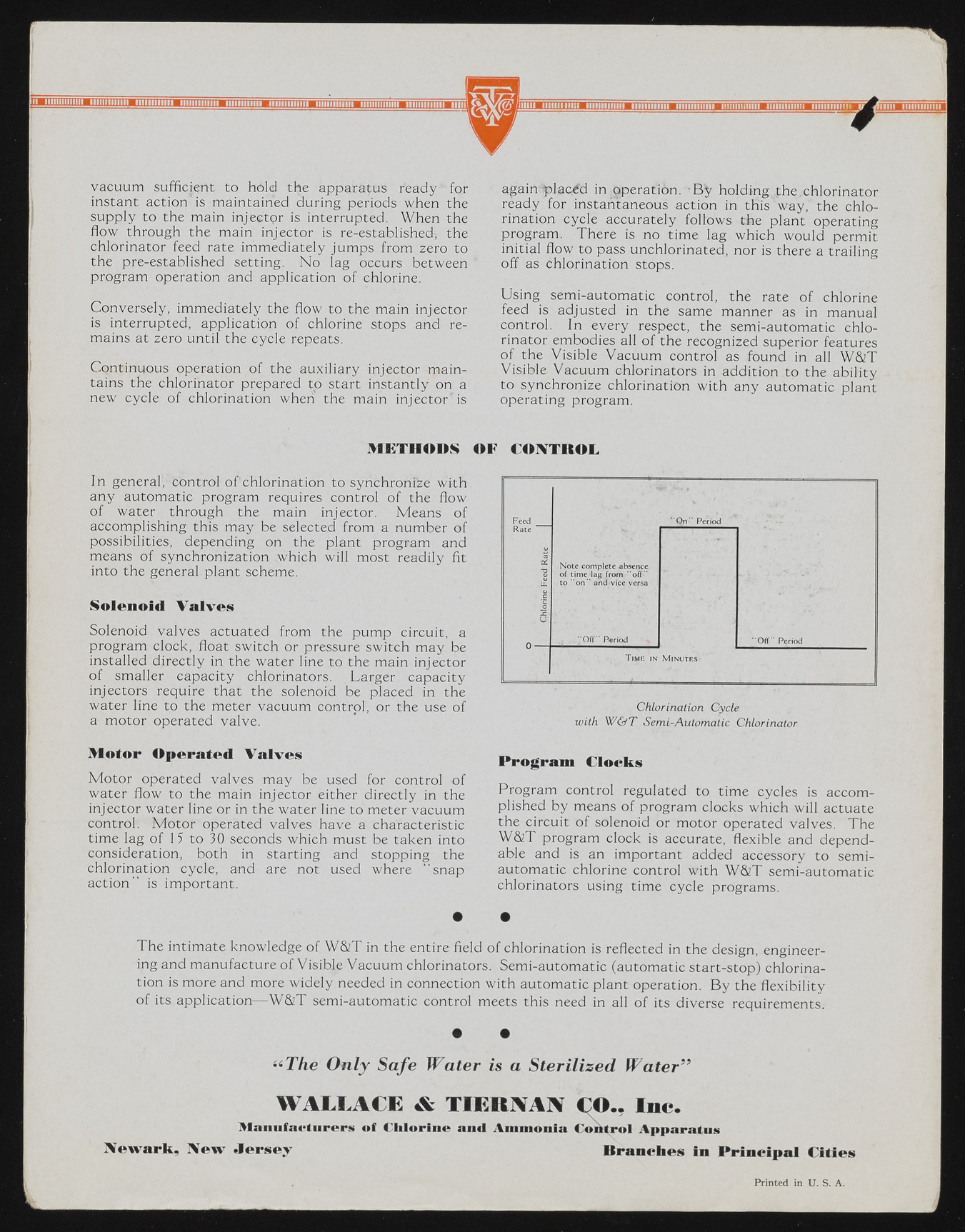

vacuum sufficient to hold the apparatus ready'''for instant action is maintained during periods when the supply to the main injectpr is interrupted. When the flow through the main injector is re-established^ the chlorinator feed rate immediately jumps from zero to the pre-established setting. N o lag occurs between program operation and application o f chlorine. Converselyllmmediately the flow to the main injector is interrupted, application of chlorine stops and remains at zero until the cycle repeats. Continuous operation of the auxiliary injector maintains the chlorinator prepared tp start instantly on a new cycle of chlorination when the main injector" is again-placed in operation. -By holding the,chlorinator ready for instantaneous action in this way, the chlorination cycle accurately follows the plant operating program. There is no time lag which would permit initial flow to pass unchlorinated, nor is there a trailing off as chlorination stops. Using semi-automatic control, the rate o f chlorine feed is adjusted in the same manner as in manual control. In every respect, the semi-automatic chlorinator embodies all of the recognized superior features of the Visible Vacuum control as found in all W &T Visible Vacuum chlorinators in addition to the ability to synchronize chlorination with any automatic plant operating program. M ETH O D S OF CONTROL “ Q n" Period o, Chlorine Feed Rc Note complete absence of time lag from "o ff” to "o n ” and'vice versa -."O ff” Period "O ff" Period T im e - in M i n u t e s - In general, control of’chlorination to synchronize with any automatic program requires control of the flow of water through the main injector. Means of accomplishing this may be selected from a number of possibilities, depending on the plant program and means of synchronization .which will most readily fit into the general plant scheme. Solenoid V alves Solenoid valves actuated from the pump circuit, a program clock, float switch or pressure switch may be installed directly in the water line to the main injector of smaller capacity chlorinators. Larger capacity injectors require that the solenoid be placed in the water line to the meter vacuum control, or the use of a motor operated valve. M o to r O p erated V alves M otor operated valves may be used for control of water flow to the main injector either directly in the injector water line or in the water line to meter vacuum control. M otor operated valves have a characteristic time lag of 15 to 30 seconds which must be taken into consideration, both in starting and stopping the chlorination cycle, and are not used where “ snap action” is important. • Chlorination Cycle with W & T Semi-Automatic Chlorinator P rogram Clocks Program control regulated to time cycles is accomplished by means of program clocks which will actuate the circuit of solenoid or motor operated valves. The W &T program clock is accurate, flexible and dependable and is an important added accessory to semiautomatic chlorine control with W &T semi-automatic chlorinators using time cycle programs. • The intimate knowledge of W &T in the entire field of chlorination is reflected in the design, engineering and manufacture of Visible Vacuum chlorinators. Semi-automatic (automatic start-stop) chlorination is more and more widely needed in connection with automatic plant operation. By the flexibility of its application— W &T semi-automatic control meets this need in all of its diverse requirements. “ The O n ly Sa fe W ater is a S te rilize d W ater” W A L L A C E & TIEfttNAN ^ © .. In c. M an u factu rers of C hlorine and A m m on ia C ontrol A pparatu s N ew ark, N ew Jersey Branches in P rincipal Cities Printed in U. S. A.