Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

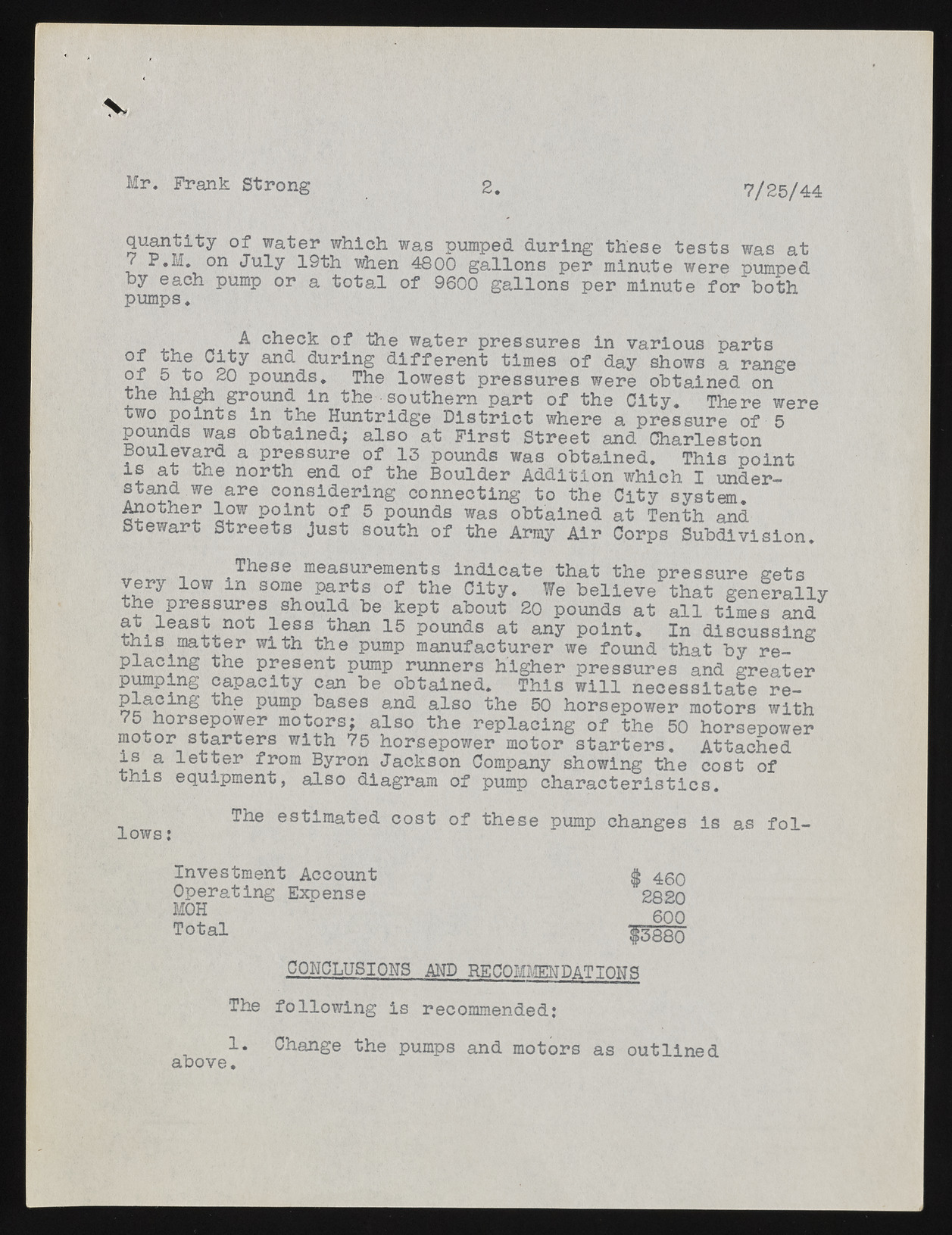

V Mr. Prank Strong 2. 7/25/44 quantity of water which was pumped during these tests was at 7 P.M. on July 19th when 4800 gallons per minute were pumped by each pump or a total of 9600 gallons pumps. per minute for both of.e. the Cit^y ac^nide c^d- uring^ lde iwffaetreern tp retsismuesr eso f ind ayv arsihoouwss pa arrtasnge of 5 to 20 pounds. The lowest pressures were obtained on the high ground in the southern part of the City. There were two points in the Huntridge District where a pressure of 5 pounds was obtained; also at First Street and Charleston Boulevard a pressure of 13 pounds was obtained. This point is at the north end of the Boulder Addition which I understand we are considering connecting to the City system. Another low point of 5 pounds was obtained at Tenth and Stewart Streets just south of the Army Air Corps Subdivision. These measurements indicate that the pressure gets very low in some parts of the City. We believe that generally the pressures should be kept about 20 pounds at all times and^ at ieast not less than 15 pounds at any point. In discussing tnis matter with the pump manufacturer we found that by replacing the present pump runners higher pressures and greater pumping capacity can be obtained. This will necessitate re-placing the pump bases and also the 50 horsepower motors with 75 horsepower motors; also the replacing of the 50 horsepower motor starters with 75 horsepower motor starters. Attached is a letter from Byron Jackson Company showing the cost of this equipment, also diagram of pump characteristics. lows: The estimated cost of these pump changes is as folInvestment Account Operating Expense MOH Total CONCLUSIONS AND RECOMMENDATIONS The following is recommended: 1 . Change the pumps and motors as outlined above. # 460 2820 600 #3880