Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

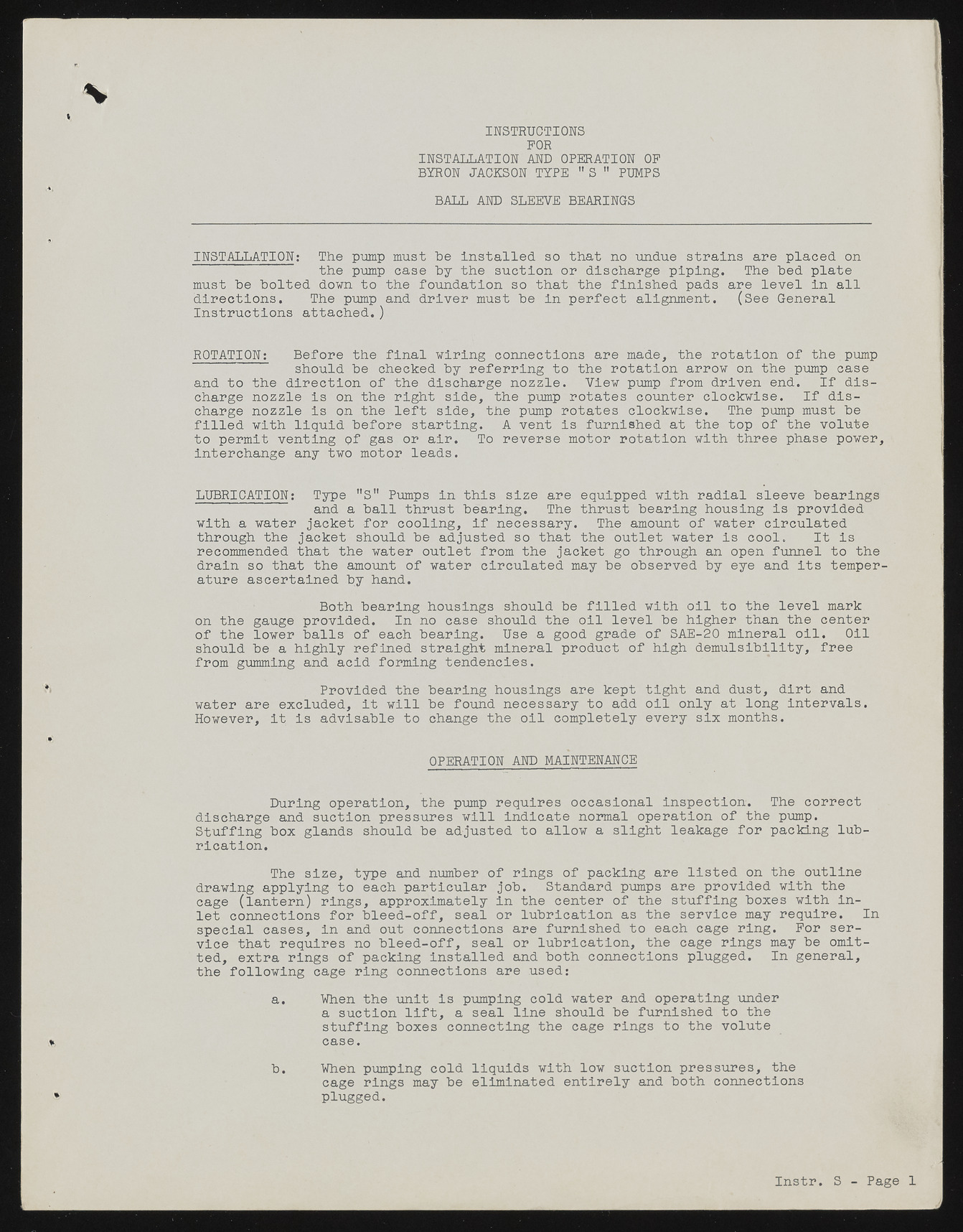

INSTRUCTIONS FOR INSTALLATION AND OPERATION OF BYRON JACKSON TYPE " S " PUMPS BALL AND SLEEVE BEARINGS INSTALLATION; The pump must he Installed so that no undue strains are placed on the pump case by the suction or discharge piping. The bed plate must be bolted down to the foundation so that the finished pads are level In all directions. The pump and driver must be in perfect alignment. (See General Instructions attached.) ROTATION; Before the final wiring connections are made, the rotation of the pump should be checked by referring to the rotation arrow on the pump case and to the direction of the discharge nozzle. View pump from driven end. If discharge nozzle is on the right side, the pump rotates counter clockwise. If discharge nozzle is on the left side, the pump rotates clockwise. The pump must be filled with liquid before starting. A vent is furnished at the top of the volute to permit venting of gas or air. To reverse motor rotation with three phase power, interchange any two motor leads. LUBRICATION; Type "S" Pumps in this size are equipped with radial sleeve bearings and a ball thrust bearing. The thrust bearing housing is provided with a water jacket for cooling, if necessary. The amount of water circulated through the jacket should be adjusted so that the outlet water is cool. It is recommended that the water outlet from the jacket go through an open funnel to the drain so that the amount of water circulated may be observed by eye and its temperature ascertained by hand. Both bearing housings should be filled with oil to the level mark on the gauge provided. In no case should the oil level be higher than the center of the lower balls of each bearing. Use a good grade of SAE-20 mineral oil. Oil should be a highly refined straight mineral product of high demulsibility, free from gumming and acid forming tendencies. K Provided the bearing housings are kept tight and dust, dirt and water are excluded, it will be found necessary to add oil only at long intervals. However, it, is advisable to change the oil completely every six months. OPERATION AND MAINTENANCE During operation, the pump requires occasional inspection. The correct discharge and suction pressures will indicate normal operation of the pump. Stuffing box glands should be adjusted to allow a slight leakage for packing lubrication. The size, type and number of rings of packing are listed on the outline drawing applying to each particular job. Standard pumps are provided with the cage (lantern) rings, approximately in the center of the stuffing boxes with inlet connections for bleed-off, seal or lubrication as the service may require. In special cases, in and out connections are furnished to each cage ring. For service that requires no bleed-off, seal or lubrication, the cage rings may be omitted, extra rings of packing installed and both connections plugged. In general, the following cage ring connections are used; When the unit is pumping cold water and operating under a suction lift, a seal line should be furnished to the stuffing boxes connecting the cage rings to the volute case. When pumping cold liquids with low suction pressures, the cage rings may be eliminated entirely and both connections plugged. I n s t r . S - Page 1