Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

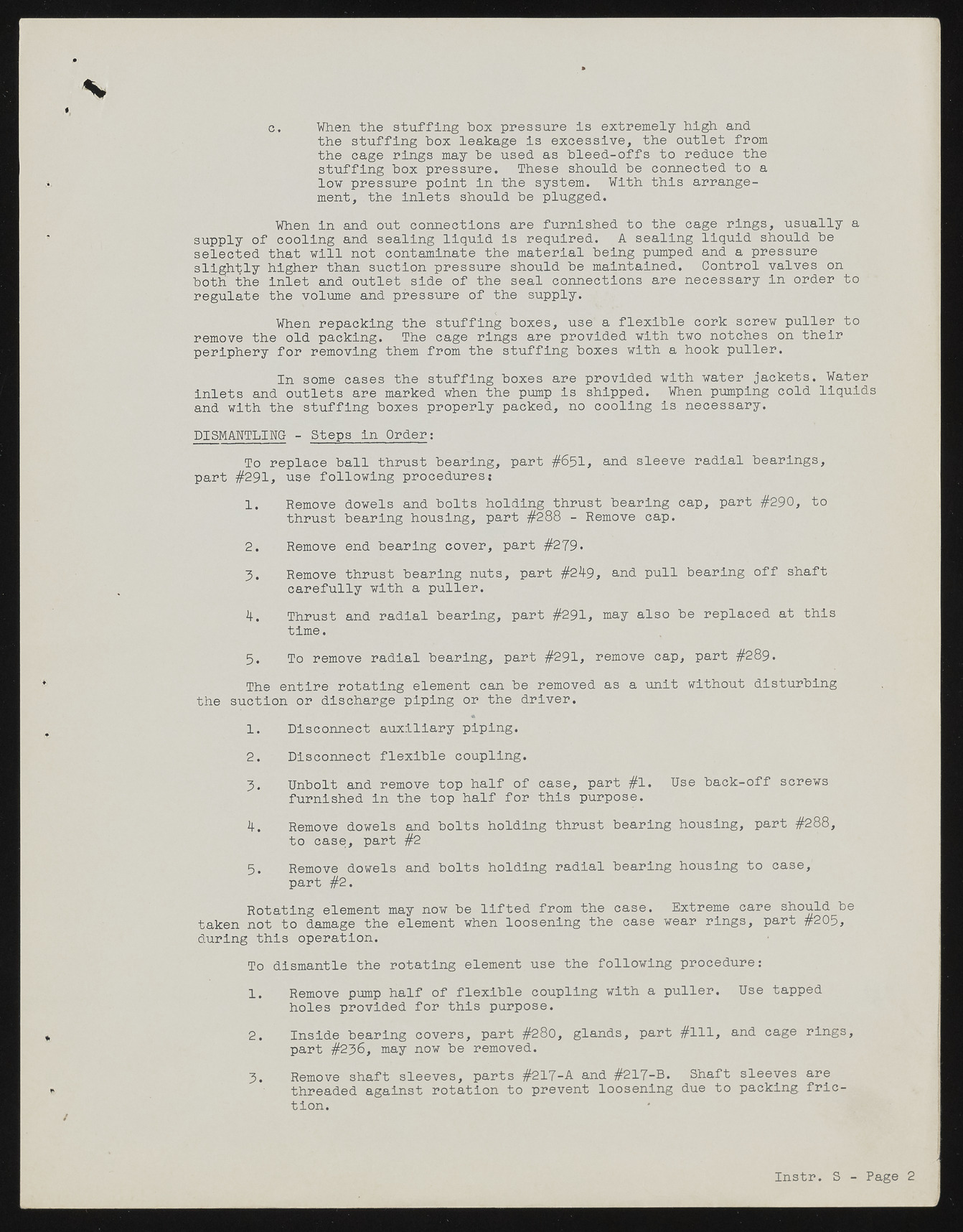

c. When the stuffing box pressure is extremely high and the stuffing box leakage Is excessive, the outlet from the cage rings may be used as bleed-offs to reduce: the stuffing box pressure. These should be connected to a low pressure point in the system. With this arrangement, the inlets should be plugged. When in and out connections are furnished to the cage rings, usually a supply of cooling and sealing liquid is required. A sealing liquid should be selected that will not contaminate the material being pumped and a pressure slightly higher than suction pressure should be maintained. Control valves on both the Inlet and outlet side of the seal connections are necessary in order to regulate the volume and pressure of the supply. When repacking the stuffing boxes, use a flexible cork screw puller to remove the old packing. The cage rings are provided with two notches on their periphery for removing them from the stuffing boxes with a hook puller. In some cases the stuffing boxes are provided with water jackets. Water inlets and outlets are marked when the pump is shipped. When pumping cold liquids and with the stuffing boxes properly packed, no cooling is necessary. DISMANTLING - Steps in Order: To replace ball thrust bearing, part #6 51, and sleeve radial bearings, part #29 1, use following proceduresj 1. Remove dowels and bolts holding thrust bearing cap, part #290, to thrust bearing housing, part #288 - Remove cap. 2. Remove end bearing c-over, part #279. 3 . Remove thrust bearing nuts, part #249, and pull bearing off shaft carefully with a puller. 4. Thrust and radial bearing, part #291, may also be replaced at this time. 5. To remove radial bearing, part #291, remove cap, part #289. * The entire rotating element can be removed as a unit without disturbing the suction or discharge piping or the driver. K 1. Disconnect auxiliary piping. 2. Disconnect flexible coupling. 3. Unbolt and remove top half of case, part #1. Use back-off screws furnished in the top half for this purpose. 4. Remove dowels and bolts holding thrust bearing housing, part #288, to case, part #2 5. Remove dowels and bolts holding radial bearing housing to case, part #2. Rotating element may now be lifted from the case. Extreme care should be taken not to damage the element when loosening the case wear rings, part #205, during this operation. To dismantle the rotating element use the following procedure: 1. Remove pump half of flexible coupling with a puller, holes provided for this purpose. Use tapped 2 . Inside bearing covers, part #280, glands, part part #236, may now be removed. # 1 1 1 , and cage rings, * 3. Remove shaft sleeves, parts #217-A and #217-B. threaded against rotation to prevent loosening Shaft due to sleeves packing. are fric-tion. In str. S - Page 2