Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

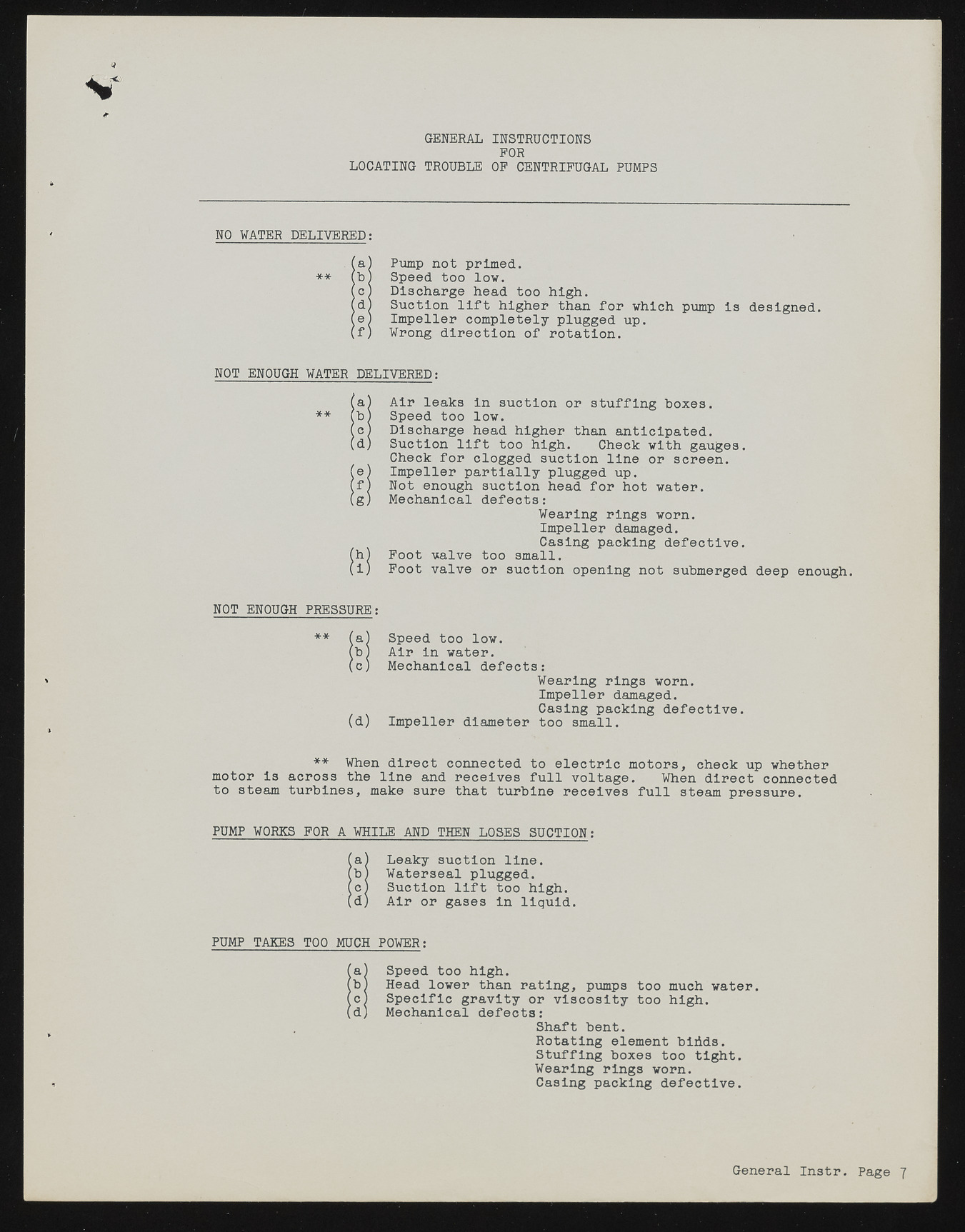

GENERAL INSTRUCTIONS FOR LOCATING TROUBLE OF CENTRIFUGAL PUMPS NO WATER DELIVERED: (a) Pump not primed. ** (b) Speed too low. (c) Discharge head too high. (d ) Suction lift higher than for which pump is designed. (e) Impeller completely plugged up. (f) Wrong direction of rotation. ** (b) Speed too low. (c ) Discharge head higher than anticipated. (d) Suction lift too high. Check with gauges. Check for clogged suction line or screen. (e) Impeller partially plugged up. if) Not enough suction head for hot water. (g) Mechanical defects: (d) Impeller diameter too small. ** When direct connected to electric motors, check up whether NOT ENOUGH WATER DELIVERED: a Air leaks in suction or stuffing boxes. Wearing rings worn. Impeller damaged. Casing packing defective. Foot valve too small. Foot valve or suction opening not submerged deep enough. NOT ENOUGH PRESSURE: ** (a) Speed too low. (b) Air in water. (c) Mechanical defects: Wearing rings worn. Impeller damaged. Casing packing defective. motor is across the line and receives full voltage. When direct connected to steam turbines, make sure that turbine receives full steam pressure. PUMP WORKS FOR A WHILE AND THEN LOSES SUCTION: Leaky suction line. Waterseal plugged. Suction lift too high. Air or gases in liquid. PUMP TAKES TOO MUCH POWER: Speed too high. Head lower than rating, pumps too much water. Specific gravity or viscosity too high. Mechanical defects: Shaft bent. Rotating element bilids. Stuffing boxes too tight. Wearing rings worn. Casing packing defective. General Instr. Page 7