Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

Member of

More Info

Rights

Digital Provenance

Publisher

Transcription

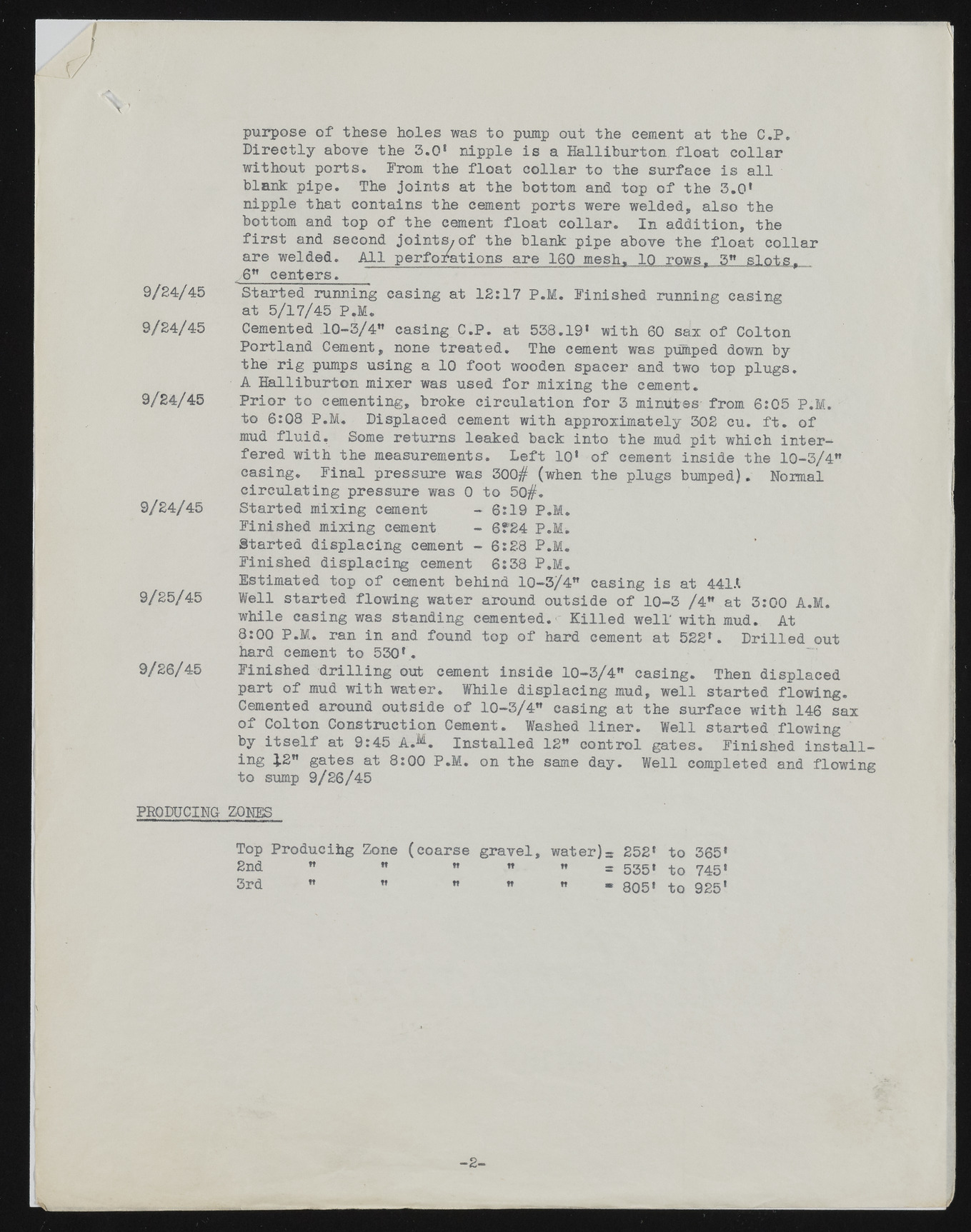

9/24/45 9/24/45 9/24/45 9/24/45 9/25/45 9/26/45 purpose o f these holes was to pump out the cement at the C.P. D ire c tly above the 3 .0 ' nipple i s a H allib u rto n flo a t c o lla r without p orts. From the flo a t c o lla r to the surface i s a l l blank pipe. The jo in ts at the bottom and top o f the 3.0* nipple that contains the cement ports were welded, also the bottom and top o f the eament flo a t c o lla r . In addition , the f i r s t and second jo in t s ,o f the blank pipe above the flo a t c o lla r are welded. A l l p erfo ration s are 160 mesh. 10 rows, 5" s lo t s , 6" centers. Started running casing at 12:17 P.M. Finished running casing at 5/17/45 P.M. Cemented .10-3/4" casing C.P. at 538.19* w ith 60 sax o f Colton Portland Cement, none treated . The cement was pumped down by the r i g pumps using a 10 foot wooden spacer and two top plu gs. A H allib u rto n mixer was used fo r mixing the cement. P r io r to cementing, broke c irc u la tio n fo r 3 minutes from 6:05 P.M. to 6:08 P.M. Displaced cement with approximately 302 cu. f t . o f mud f lu i d . Some returns leaked back into the mud p it which in te rfered w ith the measurements. L e ft 10* o f cement in side the 10-3/4" casing. F in al pressure was 300# (when the plugs bumped). Normal c irc u la tin g pressure was 0 to 50#. Started mixing cement - 6:19 P.M. Finished mixing cement - 6f24 P.M. Started d isp la c in g cement - 6:28 P.M. Finished displacin g cement 6:38 P.M. Estimated top o f cement behind 10-3/4" casing i s at 441A W ell started flow in g water around outside o f 10-3 /4" at 3:00 A.M. w hile casing was standing cemented.' K ille d w ell' with mud. At 8:00 P.M. ran in and found top o f hard cement at 522*. D r ille d out hard cement to 530*. Finished d r i l l i n g out cement in side 10-3/4" casing. Then displaced part o f mud w ith w ater. While d isp lacin g mud, w e ll started flow in g. Cemented around outside o f 10-3/4" casing at the surface w ith 146 sax o f Colton Construction Cement. Washed lin e r . W ell started flow in g by i t s e l f at 9:45 A .^ . In s t a lle d 12" control gates. Finished in s t a llin g J2" gates at 8:00 P.M. on the same day. W ell completed and flow ing to sump 9/26/45 PRODUCING ZONES Top Produeihg Zone (coarse g ra v e l, w ater}= 2nd " " n n n - 3rd " " n n *i m 252* to 365* 535* to 745* 805* to 925' - 2 -