Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

Member of

More Info

Rights

Digital Provenance

Publisher

Transcription

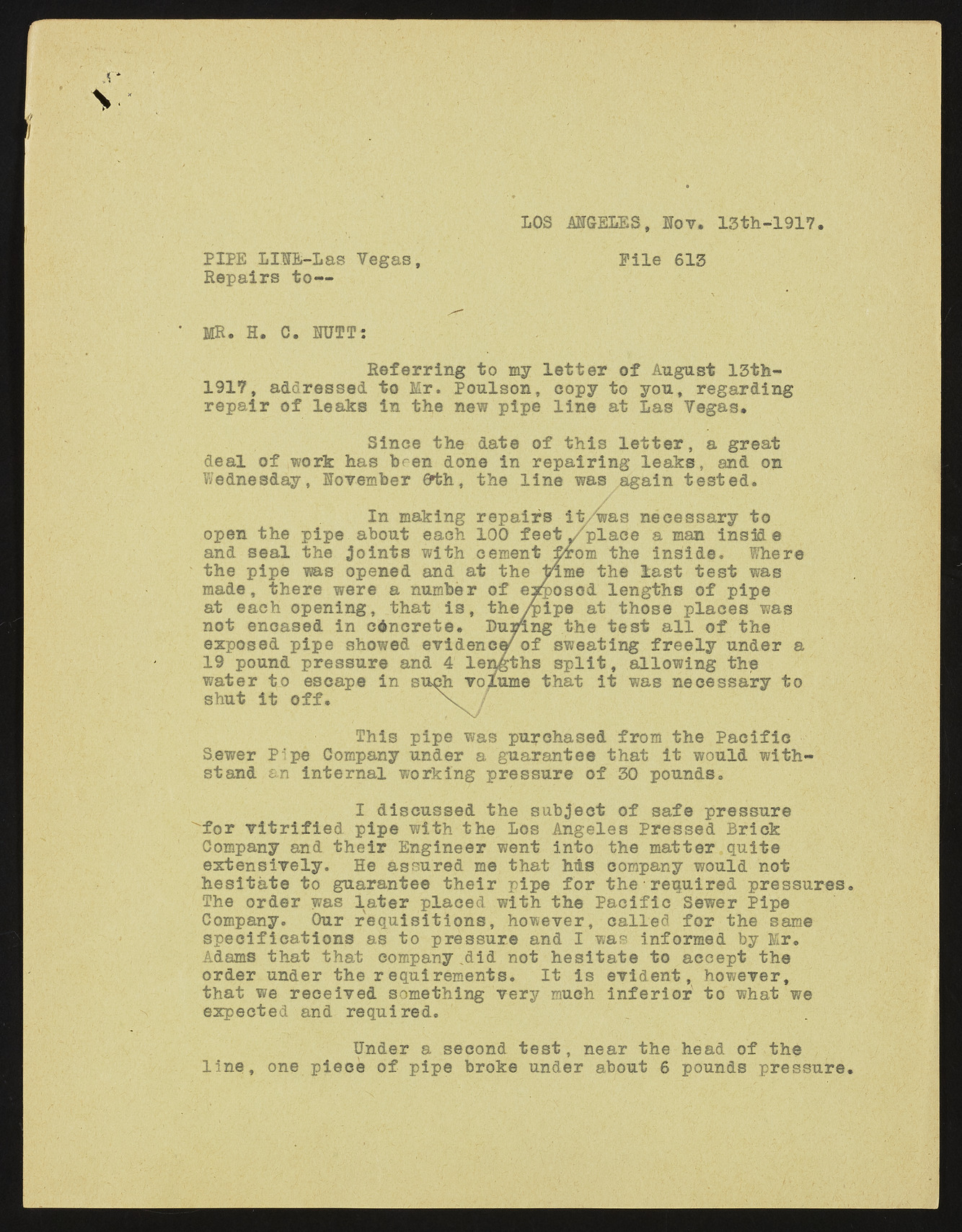

PIPE LIIB-Las Vegas, Repairs to— LOS ANGELES, Nov. 13th-1917 Pile 613 * MR. H. C. MIT: Referring to my letter of August 13th- 1917, addressed to Mr. Poulson, copy to you, regarding repair of leaks in the new pipe line at Las Vegas. Since the date of this letter, a great deal of work has been done in repairing leaks, and on Wednesday, November 6*feh, the line was again tested. In making repairs it/was necessary to open the pipe about each 100 feet yplace a man inside and seal the Joints with cement from the inside. Where the pipe was opened and at the time the last test was made, there were a number of eaposod lengths of pipe at each opening, that is, the/pipe at those places was not encased in concrete. During the test all of the exposed pipe showed evidence/of sweating freely under a 19 pound pressure and 4 lengths split, allowing the water to escape in such volume that it was necessary to shut it off. n . This pipe was purchased from the Pacific Sewer Pipe Company under a guarantee that it would withstand an internal working pressure of 30 pounds. I discussed the subject of safe pressure "•for vitrified pipe with the Los Angeles Pressed Brick Company and their Engineer went into the matter quite extensively. He assured me that his company would not hesitate to guarantee their pipe for the required pressures The order was later placed with the Pacific Sewer Pipe Company. Our requisitions, however, called for the same specifications as to pressure and I was informed by Mr. Adams that that company ^did not hesitate to accept the order under the requirements. It is evident, however, that we received something very much inferior to what we expected and required. Under a second test, near the head of the line, one piece of pipe broke under about 6 pounds pressure