Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

Member of

More Info

Rights

Digital Provenance

Publisher

Transcription

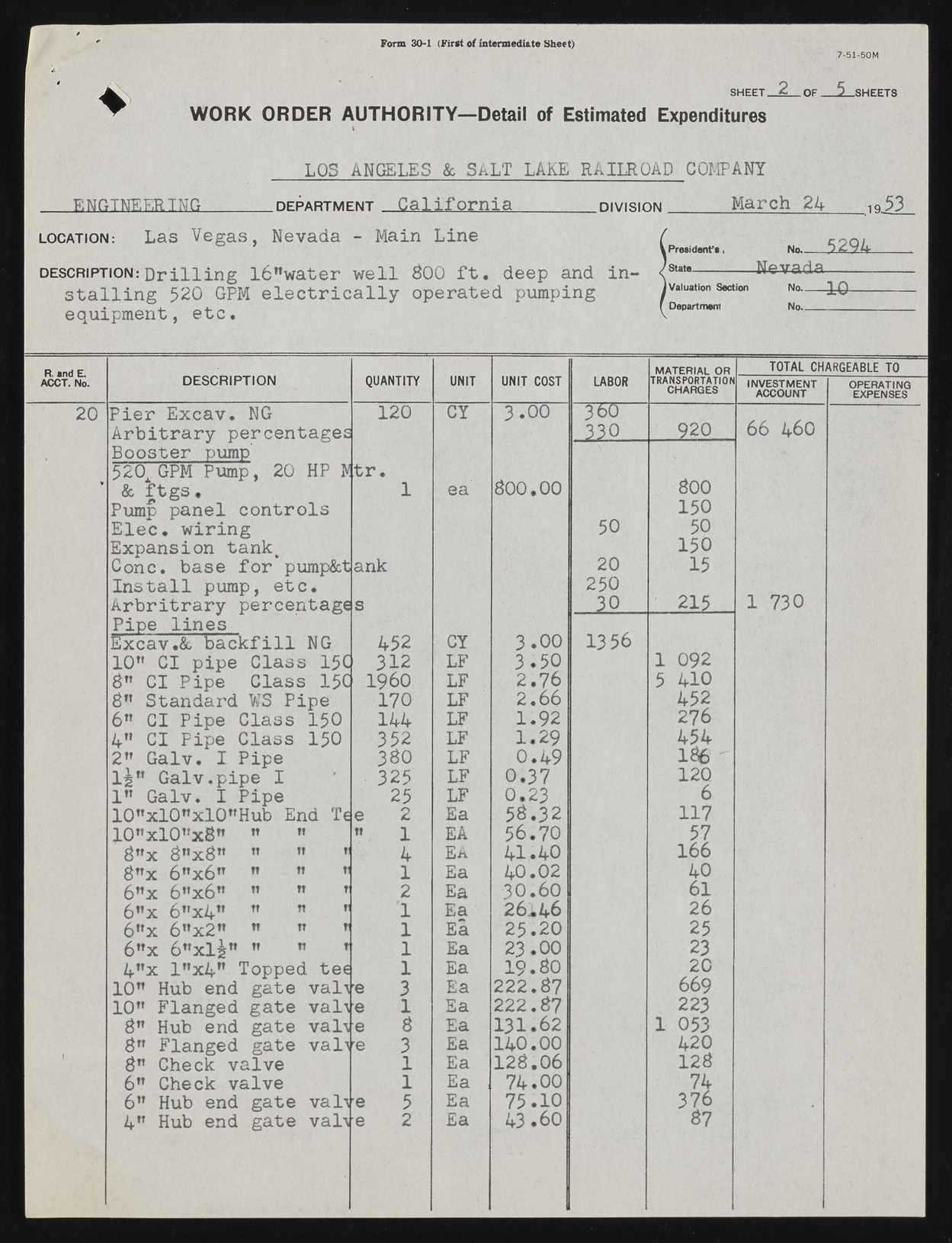

Form 30*1 (First of intermediate Sheet) 7-51-50M SHEET 2 OF 5 SHFETS W O RK O R D ER A U TH O R ITY—Detail of Estimated Expenditures LOS ANGELES & SALT LAKE RAILROAD COMPANY ENGINEERING______ department California_______ division_____ March 24 ^,53 location: Las Vegas, Nevada - Main Line description: Drilling l6"water well 800 ft. deep and in stalling 520 GPM electrically operated pumping equipment, etc. President's, State_____________ Valuation Section Department No.___5 2 9 4 ?Nev ada---- No— I Q ------ No________________ R. and E . A C C T . No. DESCRIPTION QUANTITY UNIT UNIT COST LABOR M A T E R I A L O R TRANSPORTATION C H A R G E S 20 Pier Excav. NG 120 CY 3.00 360 Arbitrary percentages 330 920 Booster pump 520. * GPM Pump, 20 HP Ntr. & ftgs. 1 ea 800.00 800 Pump panel controls 150 Elec, wiring 50 50 Expansion tank^ 150 Cone, base for pump&tank 20 15 Install pump, etc. 250 Arbritrary percentage s 30 215 Pipe lines Excav backfill NG 452 CY 3.00 1356 10" Cl pipe Class 15C 312 LF 3.50 1 092 8" Cl Pipe Class 15C I960 LF 2.76 5 410 8" Standard WS Pipe 170 LF 2.66 452 6" Cl Pipe Class 150 144 LF 1.92 276 4” Cl Pipe Class 150 352 LF 1.29 454 2” Galv. I Pipe 380 LF 0.49 136 ' 1^" Galv.pipe I 325 LF 0.37 120 ln Galv. I Pipe 25 LF 0.23 6 10"xlO"xlO"Hub End Tee 2 Ea 53.32 117 I0"xl0"x8" " " " 1 EA 56.70 57 8"x 8wx§" " « r 4 EA 41.40 166 8"x 6"x6" " " r 1 Ea 40.02 40 6"x 6»x6" " M 1 2 Ea 30.60 61 6”x 6"x4" " n T 1 Ea 26i46 26 6"x 6"x2f» n " T 1 Ea 25.20 25 6Mx 6"xl5M " " * 1 Ea 23.00 23 4”x l”x4n Topped tee 1 Ea 19.30 20 10” Hub end gate valT e 3 Ea 222.87 669 10" Flanged gate valT e 1 Ea 222.87 223 S" Hub end gate val% e 8 Ea 131.62 1 053 8" Flanged gate val-\ e 3 Ea 140.00 420 8" Check valve 1 Ea 128.06 128 6" Check valve 1 Ea 74.00 74 6" Hub end gate val-\ e 5 Ea 75.10 376 4" Hub end gate val-v e 2 Ea 43.60 37 TOTAL CHARGEABLE TO I N V E S T M E N T O P E R A T IN G A C C O U N T E X P E N S E S 66 460 1 730