Search the Special Collections and Archives Portal

Search Results

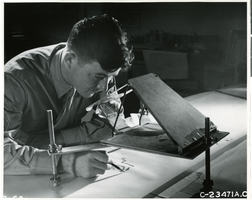

Photograph of Army Air Force officer viewing aerial photographs, circa 1940s-1950s

Date

1940 to 1959

Archival Collection

Description

An Army Air Force Compilation Technician at work transferring the pertinent terrain information from the Recto-Blique to the chart. The photograph is labeled C-23471 A. C.

Image

Photograph of worker in Hughes Machine Shop, Texas, circa 1940s-1950s

Date

1940 to 1959

Archival Collection

Description

The Hughes Laboratory machine shop is devoted to the building of full-scale test models of rock bits, tool and joints and other drilling tools for laboratory and field testing. In connection with the latter, the shop is equipped to manufacture these tools in sufficient quantities to make possible extensive and simultaneous field trials. The machine shop handles a large amount of work for the Research, Product and Metallurgical Engineering departments. This includes building new designs, new mechanisms and new devices for preliminary testing.

Image

Photograph of photographer/cameraman filiming on an airplane, circa 1940s-1950s

Date

1940 to 1959

Archival Collection

Description

A Photographer/Cameraman filming during the Operation of Akeley A-1A Motion Picture Camera and use of oxygen equipment in a Beechcraft F-2 Airplane. The photograph is labeled 12212 AC in the lower right corner and was taken by the U. S. Army Air Force.

Image

Photograph of Flight Officer in a plane on D-Day, June 6, 1944

Date

1944-06-06

Archival Collection

Description

The caption reads: "The camera is the eye of the mission." And to see that the eye is in good working order Captain Ursal P. Marshall, 522 South Furth St., Fulton, N. Y., rides along on D-Day. Captain Harvell is Photographic Officer of one of the veteran Liberator Groups which is now commanded by Colonel John H. Gibson of Hinsdale, Illinois. This photograph was taken shortly before reaching the target, in initial wave of heavy bombers on D-Day, June 6, 1944."

Image

Photograph of Hughes Laboratory Machine Shop, Houston, Texas, circa 1940s-1950s

Date

1940 to 1959

Archival Collection

Description

Men and women in the Hughes Laboratory Machine Shop are devoted to the building of full-scale test models of rock bits, tool joints and other drilling tools for laboratory and field testing. In connection with the latter, the shop is equipped to manufacture these tools in sufficient quantities to make possible extensive and simultaneous field trials. The machine shop handles a large amount of work for Research, Product and Metallurgical Engineering divisions. This includes building new designs, new mechanisms and new devices for preliminary testing.

Image

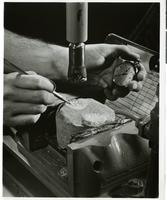

Photograph of employee in Hughes Laboratory Machine Shop, Houston, Texas, circa 1940s-1950s

Date

1940 to 1959

Archival Collection

Description

The Hughes Laboratory Machine Shop is devoted to the building of full-scale test models of rock bits, tool joints and other drilling tools for laboratory and field testing. In connection with the latter, the shop is equipped to manufacture these tools in sufficient quantities to make possible extensive and simultaneous field trials. The machine shop handles a large amount of work for Research, Product and Metallurgical Engineering division. This includes building new designs, new mechanisms and new devices for preliminary testing.

Image

Photograph of a man working on rock bit drilling pieces at the Hughes Tool Co., Houston, Texas, circa 1950s

Date

1950 to 1959

Archival Collection

Description

A man working on Hughes rock bit drilling pieces at the Hughes Tool Company in Houston.

Image

Photograph of a man working at the Hughes Tool Co., Houston, Texas, circa 1950s

Date

1950 to 1959

Archival Collection

Description

Transcribed from attached press release: "HUGHES ROCK BIT TEST In a block-long laboratory at Houston, Texas, the Hughes Tool Company can simulate oil drilling conditions anywhere in the world. Here a Hughes bit is tested on a hard formation. Howard Hughes' father invented the rock bit in 1908 and the resulting business became the cornerstone on which Howard Hughes built his fabulous industrial empire in motion pictures, air transportation, aeronautical research and design, aircraft manufacture, electronics, armament and brewing."

Image

Photograph of a drill bit at the Hughes Tool Co., Houston, Texas, circa 1950s

Date

1950 to 1959

Archival Collection

Description

Transcribed from attached press release: "LITTLE BIT Only an inch and a quarter in diameter, this "microbit" enables engineers at the Hughes Tool Company, Houston, Texas, to estimate the performance of full-size bits for the oil drilling industry. The company operates the largest testing laboratory of its kind anywhere in the world and produces thousands of rock bits necessary to drill deeper and deeper as the world's shallow oil wells have become exhausted. Howard Hughes terms the Hughes Tool company the "keystone" of his industrial empire."

Image

Photograph of the Hughes Tool Co. Drilling Laboratory, Houston, Texas, circa 1950s

Date

1950 to 1959

Archival Collection

Description

Transcribed from attached press release: "DRILLING LABORATORY The fundamental purpose of all Hughes rock bit research is to improve bit performance. In attaining this improvement it is necessary to balance design with the application of correct metallurgical materials and manufacturing methods. The preliminary proving ground is the Drilling laboratory housed in the main Laboratory building. Its field-size drilling rig, with 118 ft. derrick, was especially designed to test rock bits in a manner simulating oilfield drilling conditions."

Image

Pagination

Refine my results

Content Type

Creator or Contributor

Subject

Archival Collection

Digital Project

Resource Type

Year

Material Type

Place

Language

Records Classification