Search the Special Collections and Archives Portal

Search Results

Photograph of new atomic-hydrogen welding process, Hughes Tool Company, Houston, Texas, circa 1929

Date

1929

Archival Collection

Description

Transcribed from press release attached to back of photo: "PENETRATES EARTH 16,000 FEET A surface approaching the hardness of the diamond is applied by a new atomic-hydrogen welding process to the teeth of a rock bit drill at the Hughes Tool Company plant in Houston, Texas, owned by Howard Hughes, noted aircraft designer-flyer. The first Hughes rock bit revolutionized oil drilling practices in this nation several decades ago, making possible recovery of oil beneath hard rock formations at great depths. Most recent models have penetrated the earth below 16,000 feet. Hughes drills are used in 50 foreign countries. NOTE: The atomic-hydrogen process differs from other arc-welding processes in that the arc is formed between two electrodes, rather than one electrode and the work." The patent on the atomic-hydrogen process was awarded October 29, 1929.

Image

Photograph of museum basement floor plan, Boulder City (Nev.), February 11, 1938

Date

1938-02-11

Archival Collection

Description

Boulder City Museum basement floor plan.

Image

Minority Recruiting in the New York City Police Department by the New York City Rand Institute, 1971 May

Level of Description

File

Archival Collection

Ardis Kearns Papers

To request this item in person:

Collection Number: MS-00348

Collection Name: Ardis Kearns Papers

Box/Folder: Box 18

Collection Name: Ardis Kearns Papers

Box/Folder: Box 18

Archival Component

The Police Internal Administration of Justice in New York City by the New York City Rand Institute, 1970 November

Level of Description

File

Archival Collection

Ardis Kearns Papers

To request this item in person:

Collection Number: MS-00348

Collection Name: Ardis Kearns Papers

Box/Folder: Box 19

Collection Name: Ardis Kearns Papers

Box/Folder: Box 19

Archival Component

Unknown author. The Howard Hughes puzzle, Newsweek 71(3), 1968 January 15

Level of Description

File

Archival Collection

UNLV Libraries Collection of Articles on Gaming and Las Vegas, Nevada Topics

To request this item in person:

Collection Number: MS-00626

Collection Name: UNLV Libraries Collection of Articles on Gaming and Las Vegas, Nevada Topics

Box/Folder: Box 12

Collection Name: UNLV Libraries Collection of Articles on Gaming and Las Vegas, Nevada Topics

Box/Folder: Box 12

Archival Component

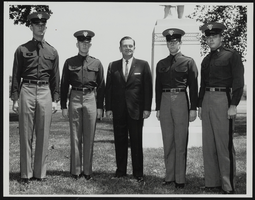

Howard Cannon visits West Point, New York with four unidentified cadets: photographic print

Date

1970-10-08

Archival Collection

Description

From the Howard Cannon Photograph Collection (PH-00192). Stamped on verso: "Signal Division File #USMA-64-1996 NR West Point New York 25 May 64 - Photo by Mr Murphy". Stamped on verso: "Please give credit as 'U.S. Army Photograph'"

Image

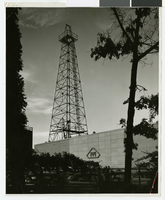

Photograph of the exterior of Hughes Research Laboratories, Culver City, California, circa 1940s

Date

1940 to 1949

Archival Collection

Description

The exterior of Hughes Research Laboratories where rock bits were test-drilled in Culver City, California in the 1940s. Transcribed from note taped to back of photo: "Rock bits are test-drilled in the laboratory under conditions that duplicate, as far as is possible in the laboratory, those encountered in actual drilling. As a result, rotational speeds, loads, and fluid volume are closely controlled. The rig operator occupies a splash-proof booth above the 'cellar floor.' The instruments on his control panel provide for application and measurement of variable axial loading on the drilling bit up to 100,000 lbs., variable rotational speeds up to 400 rpm, measurement of bit penetration over a total vertical travel of 5 feet at rates up to 180 ft. per hour, and torque. On the panel, also, are several controls for the operation of mud pump and other accessory equipment."

Image

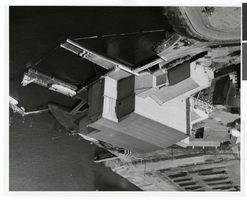

Aerial view of Hughes Helicopters Division of Summa Corporation, Culver City, California, circa late 1950s

Date

1957 to 1959

Archival Collection

Description

Hughes Helicopters Division of Summa Corporation in Culver City, California.

Image

Police escorting Howard Hughes and his crew at the Washington Airport as his around-the-world flight came to Washington, D.C. to thank Secretary of State Cordell Hull for his cooperation in clearing their take-offs, 1938 July 21

Level of Description

File

Archival Collection

Howard Hughes Public Relations Photograph Collection

To request this item in person:

Collection Number: PH-00373

Collection Name: Howard Hughes Public Relations Photograph Collection

Box/Folder: Folder 13

Collection Name: Howard Hughes Public Relations Photograph Collection

Box/Folder: Folder 13

Archival Component

Letter from [A. M. Folger] to Hugh A. Shamberger (Carson City), August 23, 1948

Date

1948-08-23

Archival Collection

Description

Request to the state engineer to expedite their permit to drill a well since the period for people to object had expired.

Text

Pagination

Refine my results

Content Type

Creator or Contributor

Subject

Archival Collection

Digital Project

Resource Type

Year

Material Type

Place

Language

Records Classification