Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

Member of

More Info

Rights

Digital Provenance

Publisher

Transcription

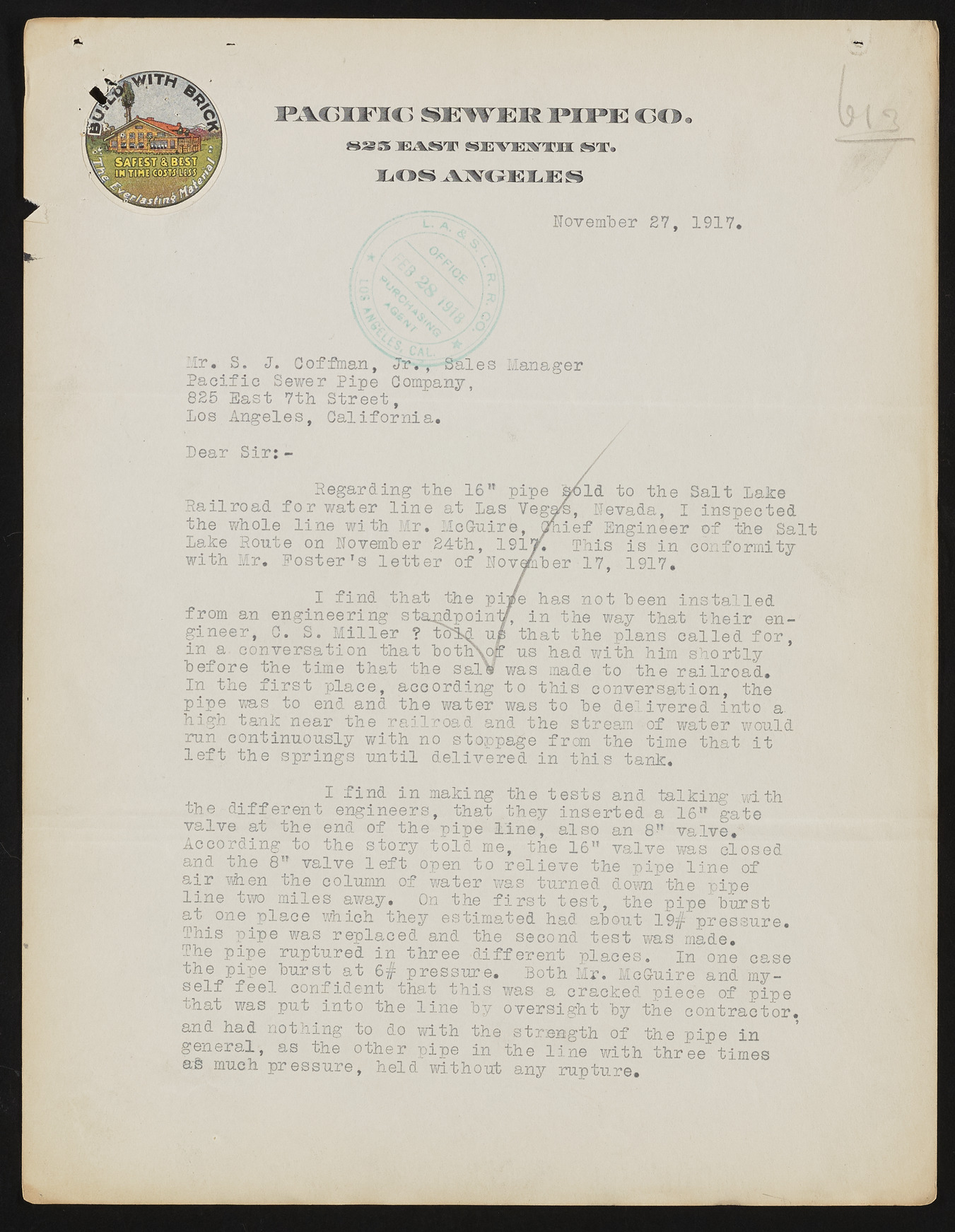

P A G I F I C S E W E R P I P E C O SSS5 EiVS'f § E V E in H s v L O S A ] ¥ G E L E S November 27, 1917 Mr. S. J. Cofflnan, Jr. , Pacific Sewer Pipe Comp; 825 East 7th Street, Los Angeles, California C ompany, Sales Manager Pear Sir / Regarding the 16" pipe &6ld to the Salt Late Railroad for water line at Las Vegas, Nevada, I inspected the whole line with Mr. McGuire, Chief Engineer of the Salt Lake Route on November 24th, 191?. This is in conformity with Mr. Poster's letter of November 17, 1917. from an engineering standpoint?, in the way that their engineer, C. S. Miller ? t i k ul that the plans called for, in a. conversation that both\ce us had with him shortly before the time that the sal® was made to the railroad. In the first place, according to this conversation, the pipe was to end and the water was to be delivered into a high tank near the railroad and the stream of water would run continuously with no stoppage from the time that it left the springs until delivered in this tank. the different engineers, that they inserted a 16" gate valve at the end of the pipe line, also an 8" valve. According to the story told me, the 16" valve was closed and the 8* valve left open to relieve the pipe line of air when the column of water was turned down the pipe line two miles away. On the first test, the pipe burst at J one place which they estimated had about 19$ pressure. This pipe was replaced and the second test was made. The pipe ruptured in three different places, in one case the pipe burst at 6# pressure. Both Mr. McGuire and myself feel confident that this was a cracked piece of pipe that was put into the line by oversight by the contractor, and had nothing to do with the strength of the pipe in general, as the other pipe in the line with three times a-.§ much pressure, held without any rupture. I find that the pi/e has not been installed I find in making the tests and talking with