Copyright & Fair-use Agreement

UNLV Special Collections provides copies of materials to facilitate private study, scholarship, or research. Material not in the public domain may be used according to fair use of copyrighted materials as defined by copyright law. Please cite us.

Please note that UNLV may not own the copyright to these materials and cannot provide permission to publish or distribute materials when UNLV is not the copyright holder. The user is solely responsible for determining the copyright status of materials and obtaining permission to use material from the copyright holder and for determining whether any permissions relating to any other rights are necessary for the intended use, and for obtaining all required permissions beyond that allowed by fair use.

Read more about our reproduction and use policy.

I agree.Information

Digital ID

Permalink

Details

More Info

Rights

Digital Provenance

Publisher

Transcription

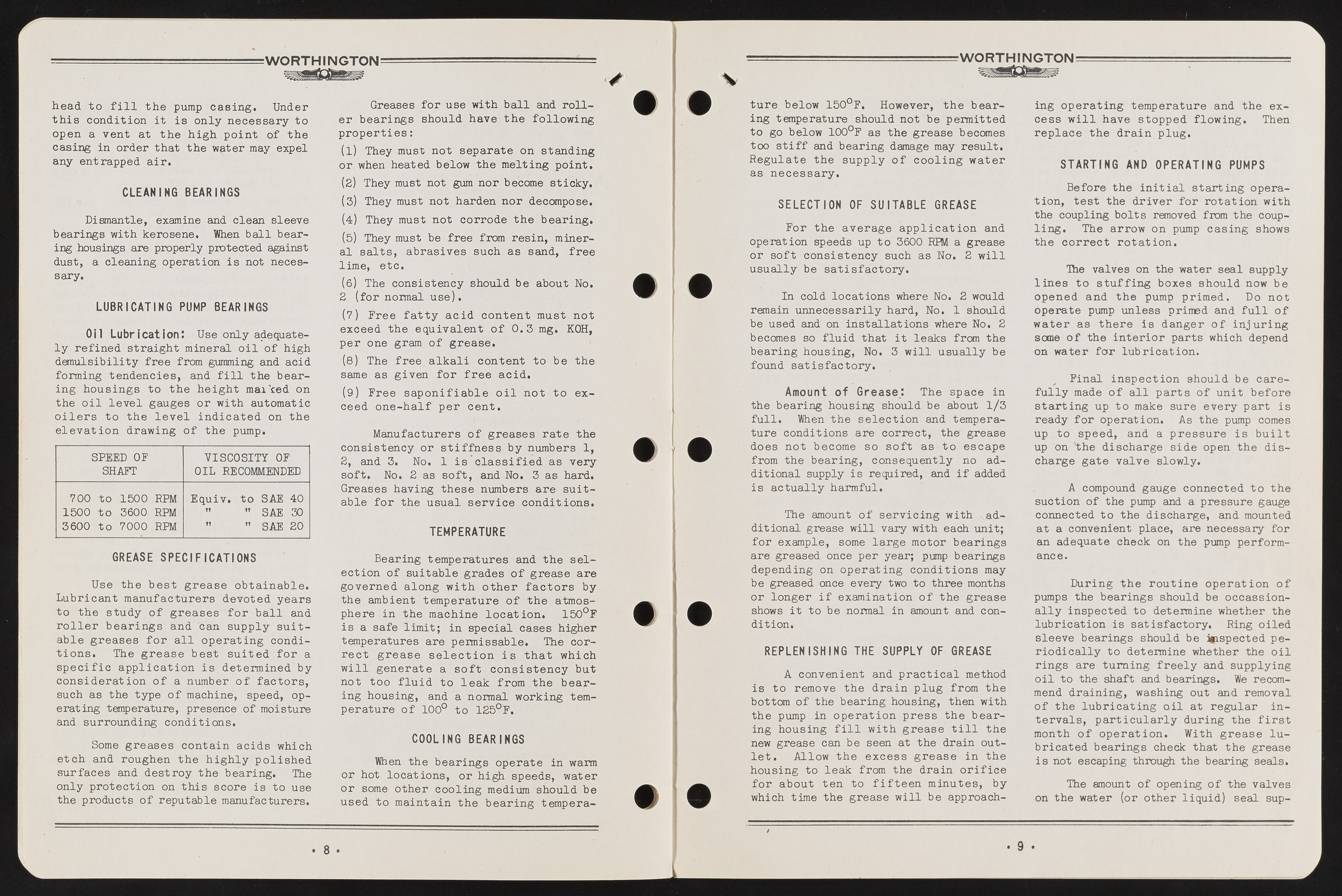

head to fill the pump casing. Under this condition it is only necessary to open a vent at the high point of the casing in order that the water may expel any entrapped air. CLEANING BEARINGS Dismantle, examine and clean sleeve bearings with kerosene. When ball bearing housings are properly protected against dust, a cleaning operation is not necessary. LUBRICATING PUMP BEARINGS ON Lubrication: Use only adequately refined straight mineral oil of high demulsibility free from gumming and acid forming tendencies, and fill the bearing housings to the height max led on the oil level gauges or with automatic oilers to the level indicated on the elevation drawing of the pump. SPEED OF SHAFT VISCOSITY OF OIL RECOMMENDED 700 to 1500 RPM 1500 to 3600 RPM 3600 to 7000 RPM Equiv. to SAE 40 " " SAE 30 " " SAE 20 GREASE SPECIFICATIONS Use the best grease obtainable. Lubricant manufacturers devoted years to the study of greases for ball and roller bearings and can supply suitable greases for all operating conditions. The grease best suited for a specific application is determined by consideration of a number of factors, such as the type of machine, speed, operating temperature, presence of moisture and surrounding conditions. Some greases contain acids which etch and roughen the highly polished surfaces and destroy the bearing. The only protection on this score is to use the products of reputable manufacturers. Greases for use with ball and roller bearings should have the following properties: (1) They must not separate on standing or when heated below the melting point. (2) They must not gum nor become sticky. (3) They must not harden nor decompose, (4) They must not corrode the bearing. (5) They must be free from resin, mineral salts, abrasives such as sand, free lime, etc. (6) The consistency should be about No. 2 (for normal use). (7) Free fatty acid content must not exceed the equivalent of 0.3 mg. KOH, per one gram of grease. (8) The free alkali content to be the same as given for free acid. (9) Free saponifiable oil not to exceed one-half per cent. Manufacturers of greases rate the consistency or stiffness by numbers 1, 2, and 3. No. 1 is classified as very soft. No. 2 as soft, and No. 3 as hard. Greases having these numbers are suitable for the usual service conditions. TEMPERATURE Bearing temperatures and the selection of suitable grades of grease are governed along with other factors by the ambient temperature of the atmosphere in the machine location. 150°F is a safe limit; in special cases higher temperatures are peimissable. The correct grease selection is that which will generate a soft consistency but not too fluid to leak from the bearing housing, and a normal working temperature of 100° to 125°F. COOLING BEARINGS Mien the bearings operate in warm or hot locations, or high speeds, water or some other cooling medium should be used to maintain the bearing tempera• 8 • V W O R TH IN G TO N ture below 150°F. However, the bearing temperature should not be permitted to go below 100°F as the grease becomes too stiff and bearing damage may result. Regulate the supply of cooling water as necessary. SELECTION OF SUITABLE GREASE For the average application and operation speeds up to 3600 RPM a grease or soft consistency such as No. 2 will usually be satisfactory. In cold locations where No. 2 would remain unnecessarily hard, No. 1 should be used and on installations where No. 2 becomes so fluid that it leaks from the bearing housing, No. 3 will usually be found satisfactory. Amount o f G rease: The space in the bearing housing should be about 1/3 full. When the selection and temperature conditions are correct, the grease does not become so soft as to escape from the bearing, consequently no additional supply is required, and if added is actually harmful. The amount of servicing with additional grease will vary with each unit; for example, some large motor bearings are greased once per year; pump bearings depending on operating conditions may be greased once every two to three months or longer if examination of the grease shows it to be normal in amount and condition. REPLENISHING THE SUPPLY OF GREASE A convenient and practical method is to remove the drain plug from the bottom of the bearing housing, then with the pump in operation press the bearing housing fill with grease till the new grease can be seen at the drain outlet. Allow the excess grease in the housing to leak from the drain orifice for about ten to fifteen minutes, by which time the grease will be approaching operating temperature and the excess will have stopped flowing. Then replace the drain plug. STARTING AND OPERATING PUMPS Before the initial starting operation, test the driver for rotation with the coupling bolts removed from the coupling. The arrow on pump casing shows the correct rotation. The valves on the water seal supply lines to stuffing boxes should now be opened and the pump primed. Do not operate pump unless primed and full of water as there is danger of injuring some of the interior parts which depend on water far lubrication. Final inspection should be carefully made of all parts of unit before starting up to make sure every part is ready for operation. As the pump comes up to speed, and a pressure is built up on 'the discharge side open the discharge gate valve slowly. A compound gauge connected to the suction of the pump and a pressure gauge connected to the discharge, and mounted at a convenient place, are necessary for an adequate check on the pump performance. During the routine operation of pumps the bearings should be occassion-ally inspected to determine whether the lubrication is satisfactory. Ring oiled sleeve bearings should be inspected periodically to determine whether the oil rings are turning freely and supplying oil to the shaft and bearings. Vile recommend draining, washing out and removal of the lubricating oil at regular intervals, particularly during the first month of operation. With grease lubricated bearings check that the grease is not escaping through the bearing seals. The amount of opening of the valves on the water (or other liquid) seal sup-t • 9 •